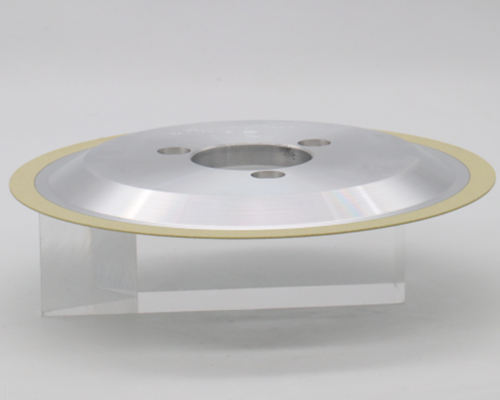

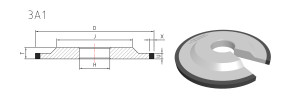

►Model: 3A1

► Dressing high precision diamond roller

► Bond: vitrified bond

► Applicable grinding machines: WAIDA, WASINO, PROFILTEC, PETEWE, DOEBLI, etc.

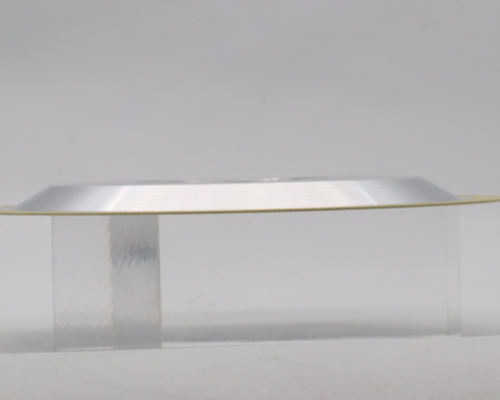

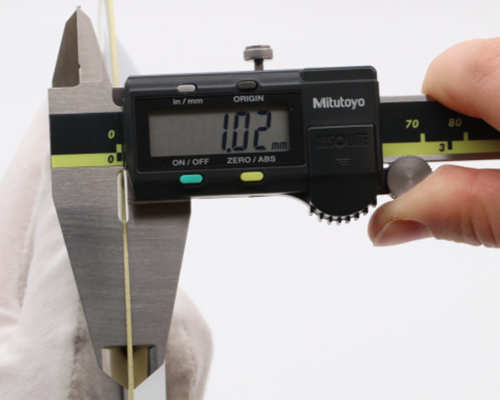

► Abrasive layer thickness up to 1mm

Diamond Rotary Tools

The diamond roller is a high-efficiency, long-life, low-cost grinding wheel dressing tool for special machine tools and gear grinding machines for mass profile grinding.

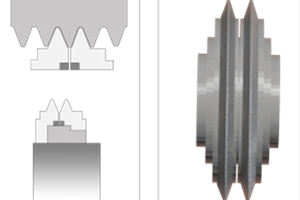

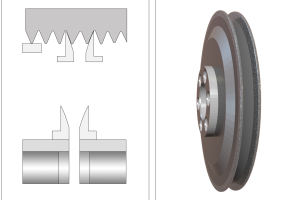

Working principle of the diamond roller

The working principle of the diamond roller is: by being installed on the dressing device of the grinding machine, the diamond roller dresses the ordinary ceramic grinding wheel or CBN grinding wheel. Grinding the parts after the grinding wheel is formed, so that the contour, precision and size of the diamond roller are copied to the surface of the processed part through the grinding wheel.

Used for high-precision electroplated diamond/CBN grinding wheel, electroplated diamond roller, etc.

Moresuperhard provides customized ceramic optical profile grinding wheels for dressing high-precision diamond rollers. Electroplated/sintered diamond rotary dresser need to undergo repeated grinding and testing on the grinding machine during the production process to maintain the corresponding size and precision. The vitrified diamond grinding wheel has the advantages of less wear and tear when dressing high-precision rollers, maintaining good shape accuracy, ensuring small linearity errors of the profile generatrix, reducing grinding burns, reducing surface roughness, and prolonging the service life of the rollers.

Application fields of vitrified diamond optical profile grinding wheel

Vitrified diamond optical profile grinding wheel is used for grinding and dressing of high-precision electroplated diamond/CBN grinding wheels, electroplated diamond rollers, diamond sintered rollers, PCD/CBN/MCD tools, diamond grinding wheels, wear-resistant parts and various diamond tools.

Supporting special grinding machines: WAIDA, WASINO, PROFILTEC, PETEWE, DOEBLI, etc.

Specification of optical profile grinding wheel

| Model | D(mm) | H(mm) | T | U | X | Grit |

| 3A1 |

125 150 200 |

22 31.75 |

10 |

1 1.2 1.5 2 |

5 10 |

#200~ |

| Other specifications and sizes can be customized according to drawings | ||||||

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

"Hyperion invests in a U.S. diamond and CBN manufacturing center, driving advancements in the superhard materials industry. Moresuperhard ’s PCD laser cutting machine delivers high-precision, heat-free, and efficient cutting solutions for PCD tool manufacturers, enhancing productivity and competitiveness."

PDC cutters are widely used for gas,oli drilling,coal minning etc.Grinding procession will directly influence the quality od PCD cutter.Moresuperhard provide diamond grinding wheel for grinding different parts of pdc cutter like surface grinding,external grinding wheel ,double-sided grinding disc and centerless grinding wheel.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088