Recently, Hyperion Materials & Technologies, a global leader in superhard materials manufacturing, announced its investment in a diamond and CBN manufacturing center in the United States. This initiative aims to enhance global supply chain stability and further drive the development of the superhard materials industry. This move not only highlights the strong market demand for high-performance superhard materials but also signals a new wave of technological upgrades in the PCD (polycrystalline diamond) tool processing industry.

New Trends in PCD Processing: Breakthroughs in Laser Cutting Technology

PCD tools, known for their exceptional wear resistance and high-efficiency machining capabilities, are widely used in aerospace, automotive manufacturing, electronics, and high-end manufacturing industries. However, due to the extreme hardness of PCD materials, processing them is highly challenging. Traditional electrical discharge machining (EDM) and grinding methods have increasingly shown drawbacks such as low efficiency and significant processing damage. To adapt to industry trends, laser cutting technology has emerged as a new solution, offering non-contact processing, high precision, and minimal material damage.

Moresuperhard's PCD Laser Cutting Machine—The Ideal Solution for High-Efficiency Precision Machining

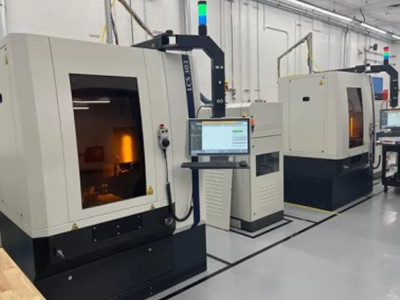

As a professional supplier in the field of superhard material processing, Moresuperhard has introduced a high-performance PCD laser cutting machine to meet the demand for efficient and precise cutting by PCD tool manufacturers.

1. High-Precision Cutting: Utilizes advanced ultrafast laser technology to achieve micron-level precision cutting, effectively reducing tool edge damage and extending tool lifespan.

2. No Heat-Affected Zone: Unlike traditional EDM processing, laser cutting does not generate a heat-affected zone on PCD materials, preventing microcracks and thermal damage, thereby improving tool quality.

3. High-Speed Processing: Laser cutting is significantly faster than traditional mechanical grinding, greatly improving production efficiency and making it ideal for large-scale PCD tool production.

4. Flexible Processing Capability: Suitable for PCD blades of various shapes and sizes, eliminating the need for complex fixture changes and significantly enhancing production flexibility.

Empowering PCD Processing, Driving Industry Upgrades

Hyperion’s construction of a diamond and CBN manufacturing center in the U.S. indicates that the superhard materials industry is moving toward higher-end and smarter solutions. As a leading PCD processing equipment provider, Moor’s PCD laser cutting machine will offer global PCD tool manufacturers more efficient and precise processing solutions, aiding industry advancements.

With the ongoing trend of intelligent and precise manufacturing, selecting advanced PCD processing equipment has become crucial for enhancing competitiveness. Moresuperhard will continue to focus on the superhard materials processing sector, providing customers with superior products and technical support, collectively driving the PCD tool processing industry to new heights.

Contact us to learn more about PCD laser cutting machines and explore the future of superhard material processing together!

Email:pcd@moresuperhard.com

Whatsapp:+86 17700605088

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088