Diamond grinding wheel for PCD wear parts

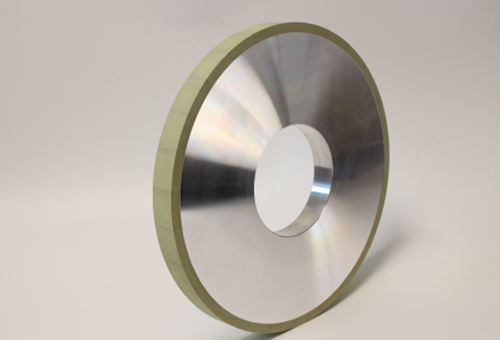

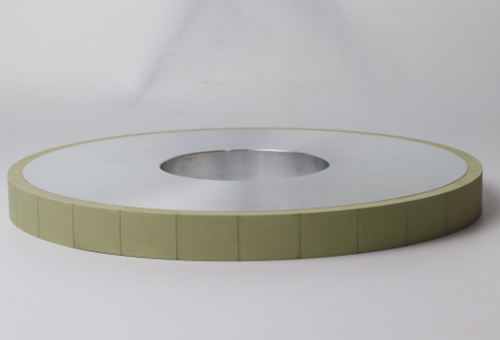

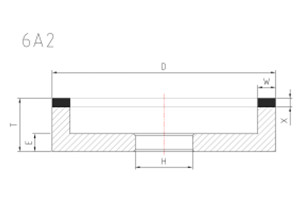

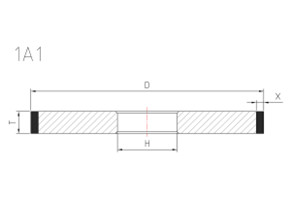

Mold:6A1,1A1

Bonded:vitrified bond or ceramic bond

Grain Sizes:200#-3000#

Worpieces:PCD wears parts used in various machine

High efficient and good wear resistance

PCD Wear Parts

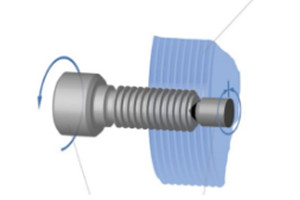

Wear refers to the continuous loss of material from a solid surface, caused by mechanical, thermal or chemical influences in contact with solids, liquids or gases caused by the surface. Therefore, use the hardest material for easy grinding Damaged Parts: Diamond

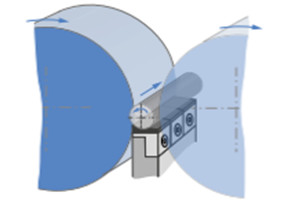

PCD Wear parts Classifications:PCD support parts;PCD workpieces guide;PCD top notch;PCD bars for centerless grinding machine

Applications of PCD wear parts

PCD bars for centerless grinder PCD tips

Vitrified diamond grinding wheel is suitable for grinding PCD materials.Therefor vitrified diamond grinding wheel is also suitable for grinding PCD wear parts.PCD wear parts have big PCD aera need to grind.Moresuperhard provide sharpen vitrified diamond grinding wheel for grinding PCD wear parts.

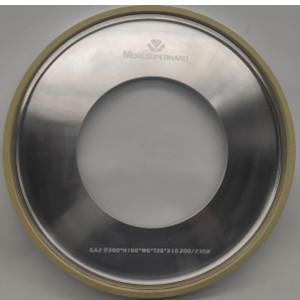

6A2 vitrified diamond cup wheel for grinding pcd wear parts

Cylindrical diamond grinding wheel for grinding pcd wear parts

Moresuperhard research and development spcific formulation vitrified diamond grinding wheel for grinding pcd wear parts.

1.Very long servives life help you decrease costs.

2.High grinding efficient

3.Easr to dress ensure grinding precision

4.Customized specification for different grinding machine

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

"Hyperion invests in a U.S. diamond and CBN manufacturing center, driving advancements in the superhard materials industry. Moresuperhard ’s PCD laser cutting machine delivers high-precision, heat-free, and efficient cutting solutions for PCD tool manufacturers, enhancing productivity and competitiveness."

PDC cutters are widely used for gas,oli drilling,coal minning etc.Grinding procession will directly influence the quality od PCD cutter.Moresuperhard provide diamond grinding wheel for grinding different parts of pdc cutter like surface grinding,external grinding wheel ,double-sided grinding disc and centerless grinding wheel.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088