Grinding

Home / Grinding / PCD Grinding Machine > H400 Precision CNC peripheral grinder

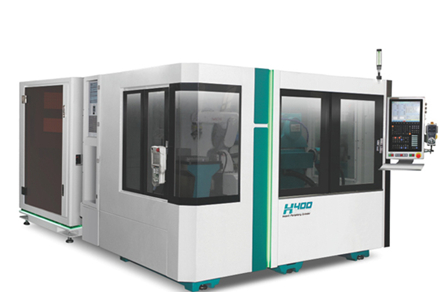

*Advanced numerical control system

*Four-axis grinding centerfour-axis grinding center

*Loading and unloading by six-axis robot

*Realize various angle rotation

*Super rigid structure, excellent precision performance

*Equipped with analog function dialogue programming software

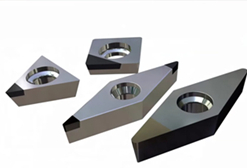

Application:suitable for the grinding of PCD/CBN/MCD, cemented carbide, ceramics and other materials for grooving and cutting off tools

Machine characteristics:

This equipment belongs to a four-axis grinding center, which is mainly suitable for the grinding of PCD/CBN/MCD, cemented carbide, ceramics and other materials for grooving and cutting off tools. It adopts advanced numerical control system, and can realize loading and unloading by six-axis robot, which can realize various angle rotation, reducing blade turning process, further improving efficiency and shortening grinding time. The grinding of various standard and non-standard tools can also be realized by changing the fixture.

Advantages of H400 high precision CNC peripheral grinding machine:

H400 high-precision CNC peripheral grinder is in a leading position in terms of design concept and manufacturing technology.

The machine tool has been tested under the most severe environment and conditions, and has outstanding accuracy retention, suitable for the requirements from single-piece to mass production.

High precision, high rigidity, and high efficiency are the basic characteristics of this grinder, achieving a perfect combination of performance and efficiency. Due to the excellent performance and flexible design of the machine tool, it is mainly used for peripheral grinding of PCD & CBN blades, cemented carbide blades, ceramic blades and non-standard blades with complex shapes. It is fully automated and suitable for mass production.

The latest generation of user-friendly graphical programming software developed by HOTMAN & LYNUC has simple and fast settings and intuitive user interface. It does not require the operator to enter complex G codes and subroutines. The operation is simple and easy to learn, making programming and setting faster. Better user experience and operating feeling.

Application:suitable for the grinding of PCD/CBN/MCD, cemented carbide, ceramics and other materials for grooving and cutting off tools

Parameter of H400 Precision CNC peripheral grinder:

|

Item |

Unit |

Model:H400 |

|

C-axis |

||

|

Travel |

Deg |

∞ |

|

Maximum speed |

rpm |

500 |

|

Positioning accuracy |

Deg |

0.006° |

|

Repeatability |

Deg |

0.001° |

|

X-axis |

||

|

Travel |

mm |

115 |

|

Rapid feed rate |

mm/min |

10000mm/min |

|

Cutting feed rate |

mm/min |

0~3600mm |

|

Positioning accuracy |

mm |

0.005 |

|

Repeatability |

mm |

0.002 |

|

Z-axis |

||

|

Travel |

mm |

600 |

|

Rapid feed rate |

mm/min |

10000mm |

|

Cutting feed rate |

mm/min |

0~3000 |

|

Positioning accuracy |

mm |

0.01 |

|

Repeatability |

mm |

0.005 |

|

B-axis |

||

|

Travel |

Deg |

-90°~+90° |

|

Rapid feed rate |

°/s |

200 |

|

Cutting feed rate |

°/s |

0~90° |

|

Repeatability |

Deg |

0.002° |

|

Wheel shaft parameters |

||

|

Wheel diameter |

mm |

400 |

|

Rotating speed |

rpm |

0~4000 |

|

Power |

Kw |

7.5 |

|

Offline trimmer |

||

|

Wheel diameter |

mm |

150 |

|

Maximum speed |

rpm |

8000 |

|

Power |

KW |

0.8 |

|

Online dresser (optional) |

||

|

Wheel diameter |

mm |

150 |

|

Maximum speed |

rpm |

8000 |

|

Travel |

mm |

0~63 |

|

Dressing feed speed |

mm/min |

0~720 |

|

Shaft power |

Kw |

0.8 |

|

Processing parameters (Product specifications: different specifications need to replace tooling) |

||

|

Maximum thickness |

mm |

35 |

|

Maximum rotation diameter |

mm |

φ50 |

|

C-axis tooling clamping (depending on the product can be enlarged) |

||

|

Clamping force |

N |

200~2500 |

|

Installed capacity |

||

|

Total power |

KW |

25 |

|

Size (length*width*height) |

mm |

3400*3600*1900 |

|

Oil cooling filter device size (optional) |

mm |

1800*1200*1500 |

|

Net weight of machine tool |

kg |

7500 |

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088