Grinding

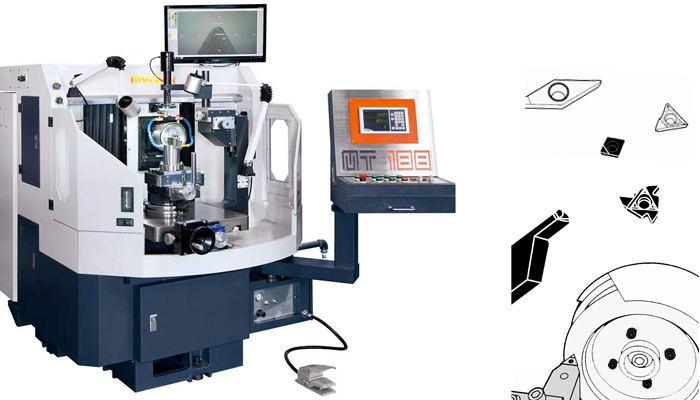

Home / Grinding / PCD Grinding Machine > MT-188 PCD PCBN Tool Grinding Machine

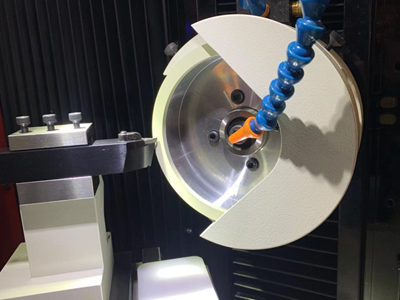

- Manual Precision machine for pcd tool grinding solutions

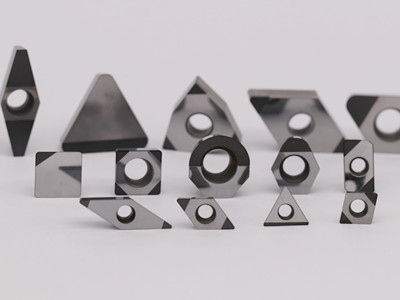

- Grinding and regrinding PCD and PCBN tools, tungsten carbide, HSS tools.

- MT-188 PCD, PCBN Tool Grinding Machine is a versatile machine and very economically, suited for manufacture and resharpen high-quality insert tools.

Manual MT-188 tool grinder is easy to operate, it can manufacture and regrind insert tools very economically. Not only grinding cutting tools which is made of PCD / PCBN, but also tungsten carbide and Hss tools.

Standard Accessories -MT 188 Tool Grinder

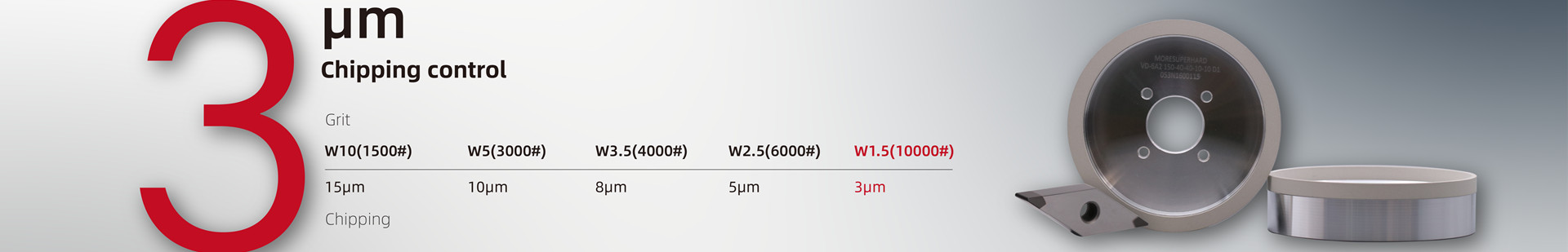

Vitrified Diamond Grinding Wheel

The vitrified diamond grinding wheel developed and produced by MoreSuperhard is matched with high-precision MT-188 tool grinder to grind pcd, pcbn, carbide, HSS tools, etc. We only choose the very strong synthetic diamond as the raw materials, make sure not only the particle shape is round enough but also be with some sharp points, which can make sure we won't lose the efficiency while we still want enough life from the wheels. So it will help you get fast, stable, much more PCD tools in unit time.

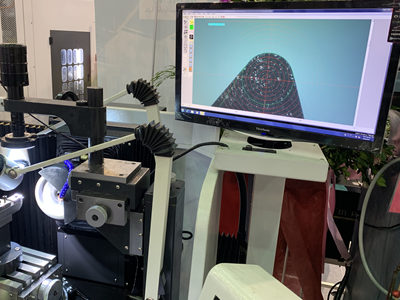

Germany Brand CCD System

The grinding machine equipped with German high-precision camers system and measurement software. The major performance features include: multiple language is available and CAD graphics and geometry in process measurement. Precision and producitiviuty has been greatly improved.

High Quality Casting Of Column and Base

The major machine elements, such as base, table and wheelhead are all analyzed by Computational Fluid Dynamics (CFD) to optimize the machine construction. This design performs the best structural dynamics with minimum deformation.

Servo Motor

Large capacity 100-liter tank with bag filters keep coolant clean for a long time to assure highest quality possible.

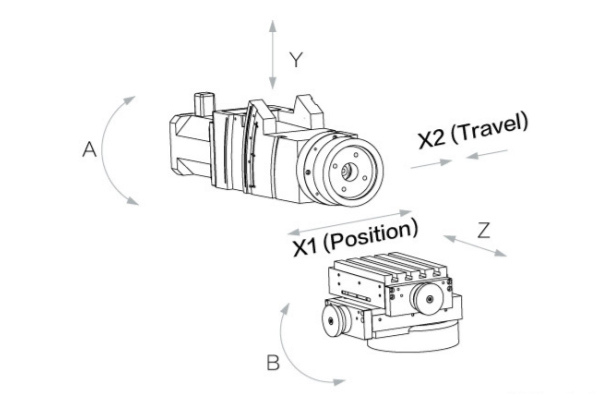

Roller Type Linear Guideway

To maximize stability and load capacity, the swing axis and position the axis are equipped with SCHNEEBERGER wide span and precision linear ways. No matter heavy duty or fine grinding, can to meet various machining requirements.

Automatic Lubricator

The automatic lubricator supplies lubrication to precision linear ways and roller ensuring high damping performance, long-term smooth feed and precise grinding.

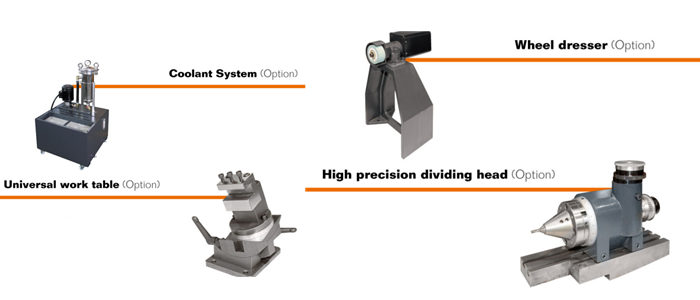

Optional Accessories - MT 188 Grinder

Universal work table

The single axis can rotate work table and dual axes can tilt work table for tool’s back angle grinding.

Wheel dresser

The workbench type wheel dresser is equipped with power motor for dressing diamond grinding wheel. The accessory now has the features of compact design, quick setups and reduction of non-cutting idle time.

High precision dividing head

For clamp round tools, the precision ground indexing plate has 24 indexing locations in 15° increments also can fine adjustment the tune the angle. They’re commonly used with NANN precision collet and flange to achieve optimal performance increase.

Parameter of MT- 188 Tool Grinder ( * V:standard O: option X:not )

|

SPEC |

MT 188 |

|

Spindle |

0-6000 rpm/min (50Hz) |

|

Vitrified grinding Wheel size |

150 x 40 x 40 |

|

Grinding pressue |

0-0.4 Mpa |

|

Grinding wheel oscillation distance |

0-40 mm |

|

Grinding wheel oscillation stroke |

40次/min |

|

Grinding wheel oscillation position |

0-188 mm |

|

Grinding wheel inclidtion |

-2°-24° |

|

Swivel table swivelling angle |

270° |

|

Table size |

210x 160x 4 slot |

|

External dimoensions |

1396 x 1601x 1582mm |

|

Y axis mpg |

x |

|

X1 axis mpg |

x |

|

X2 axis mpg |

x |

|

A axis mpg |

x |

|

Z axis air pressure |

v |

|

B axis brakes |

o |

|

Spindle with variable speed |

v |

|

Grinding wheel spindle with variable speed |

v |

|

22” lcd monitor |

v |

|

High resolution camera and measurment system |

v |

|

Tool stand |

12 16 20 25 32 |

|

Z axis dro |

v |

|

B axis dro |

v |

|

X axis dro |

o |

|

Y axis dro |

x |

|

A axis dro |

x |

|

Led work lamp |

2 pcs |

|

Grinding wheel |

3 pcs |

|

Net weight |

1800 KGS |

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088