Grinding

Home / Grinding / PCD Grinding Machine > MT-198 PCD&PCBN Tool Grinder

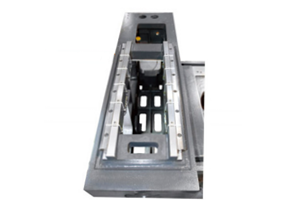

MT-198 Spindle can be raised and lowered, B axis breaking system and MPG handwheel provides added convenience in machine running test when production of special tools.

MT-198 PCD&PCBN Tool Grinding Machine, is a versatile machine, perfectly suitable for manufacture and resharpen high-quality tools.

The high-end machine,MT-198 has creative technologies to make it convenience to machine a wide range of special tools such as, spindle can be vertical movement, B axis breaking system and MPG handwheel for easy setting and running test.

Standard Accessories

.png)

Roller Type Linear Guidew

To maximize stability and load capacity, the swing axis and position the axis are equipped with SCHNEEBEGGER wide span and precision linear ways. No matter heavy duty or fine grinding, can to meet various machining requirements.

MPG(MT-198 Standard)

The MPG handwheel provides added convenience in machine runing test.

Automatic Lubricator

The automatic lubricator supplies lubrication to precision linear ways and roller ensuring high damping performance, long-term smooth feed and precise grinding.

Servo Motor

The brushless servo spindle motor is much better than tradition motors that has the features of smaller, lighter, higher-torque, high-efficiency (2.2KW) and Max. Speed 6000 rpm/min.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

"Hyperion invests in a U.S. diamond and CBN manufacturing center, driving advancements in the superhard materials industry. Moresuperhard ’s PCD laser cutting machine delivers high-precision, heat-free, and efficient cutting solutions for PCD tool manufacturers, enhancing productivity and competitiveness."

PDC cutters are widely used for gas,oli drilling,coal minning etc.Grinding procession will directly influence the quality od PCD cutter.Moresuperhard provide diamond grinding wheel for grinding different parts of pdc cutter like surface grinding,external grinding wheel ,double-sided grinding disc and centerless grinding wheel.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088