Grinding

Home / Grinding / PCD Grinding Machine > BDM-901D Manual PCD Grinding Machine

Type:manual pcd grinding machine

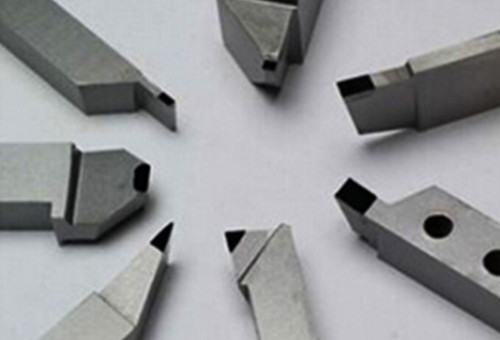

Workpieces:PCD,CBN inserts,saw blades,ceramic tools,carbide tools,HSS tools etc.

Tip Radius: R0.1mm-6mm

Grinding /Regrinding various cutting tools

Online detection and online dressing

BDM-901D is a manual high-efficient universal grinding machine suitable for processing inserts, circuit board cutter, wood circular saws, engraving cutters, turning cutters, boring cutters etc. Processed materials include PCD, CBN, ceramics, carbide, HSS. The machine is used for tools production and/or tools regrinding.

Applications

PCD/CBN inserts,PCD/CBN saw blades,ceramic tools,carbide tools,HSS tools etc.

Features of BDM-901D PCD grinding machine

1.Low-vibration, high-strength grey cast iron machine base.

2. 7 linear axes,3 rotation axes.

3. 5.5kW high-power electric spindle.

4. Pivot up and down structure.

5. The on-line inspection, optical tube and industrial PC system with CCD camera for measurement and inspection during grinding process.

6. Equip with optical scale, encoder and digital display meter for accurate positioning display

Paraments of BDM-901D grinding machine

| Grinding spindle inclination | -5°-25° |

| Tip radius | R0.1-R6mm |

| Grinding spindle speed | 1000-3000rpm |

| Grinding spindle oscillation frequency | 30 strokes/min |

| Grinding spindle oscillation size | 0-40mm |

| Grinding spindle motor power | 5.5kW |

| Grinding wheel size | Φ150×Φ40×40mm |

| Inspection system accuracy | <0.01mm |

| Image magnification | 10-65x |

| Object distance of optical tube | 300mm |

| Monitor sizes | 17〞 |

| Monitor resolution | 1280×1024 |

| Optical scale length | 120mm |

| Optical scale resolution | 0.001mm |

| Number of pulses in encoder | 2500 pulses/turn |

| Encoder resolution | 0.036° |

| Total power | 6kw |

| Dimension | 1230*1330*1770 |

| Net weight | About 1300kg |

Standard configuration

Main part of machine

Power supply and control system

Coolant system

On-line inspection system

Positioning display system

Machine light and LED ring light

Quick clamping fixture

Dressing attachment

Standard accessories

Technical documents

Accessories

Dividing attachment

Mounting onto the cross worktable, used for grinding circuit board cutter, wood circular saws.

ER40/ER50 collets, Φ3-Φ26mm/Φ6-Φ34mm.

Concentricity on clamping taper 0.004mm.

Division accuracy 0.2°.

24 division, 30 division, 40 division, 60 division for choice.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

"Hyperion invests in a U.S. diamond and CBN manufacturing center, driving advancements in the superhard materials industry. Moresuperhard ’s PCD laser cutting machine delivers high-precision, heat-free, and efficient cutting solutions for PCD tool manufacturers, enhancing productivity and competitiveness."

PDC cutters are widely used for gas,oli drilling,coal minning etc.Grinding procession will directly influence the quality od PCD cutter.Moresuperhard provide diamond grinding wheel for grinding different parts of pdc cutter like surface grinding,external grinding wheel ,double-sided grinding disc and centerless grinding wheel.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088