Grinding

Home / Grinding / PCD Grinding Machine > Ultrasonic wire die grinding machine

Applications:Wire drawing dies inner hole grinding

Grindable materials:PCD,ND,MCD,carbide

Range of die sizes:0.3mm-15mm

Ultrasonic technology greatly improves grinding efficiency and achieves very high precision

Ultrasonic Wire Die Polishing Machine

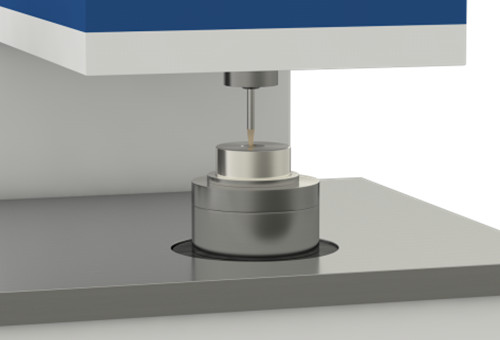

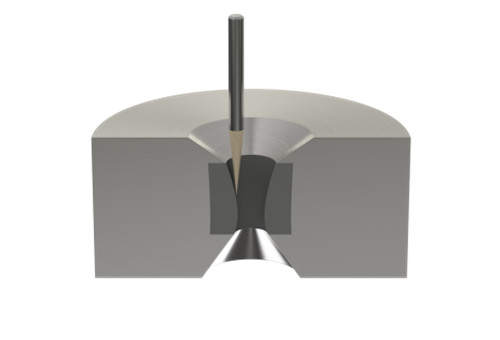

Ultrasonic wire drawing die grinder is a device that uses ultrasonic technology to precisely grind and polish wire drawing dies. Wire drawing dies are tools used to draw metal wires in metal processing, and their surface quality directly affects the surface finish and dimensional accuracy of the wires.

Moresuperhard Ultrasonic Die Polishing Machine is designed and developed for polishing and sizing of Natural diamond wire drawing dies, single crystal diamond wire dies and Polycrytalline diamond wire drawing dies for optimum die perfomace and longer die life. It’s consists of ultrasonic generator, Transducer and Oscillating die table.

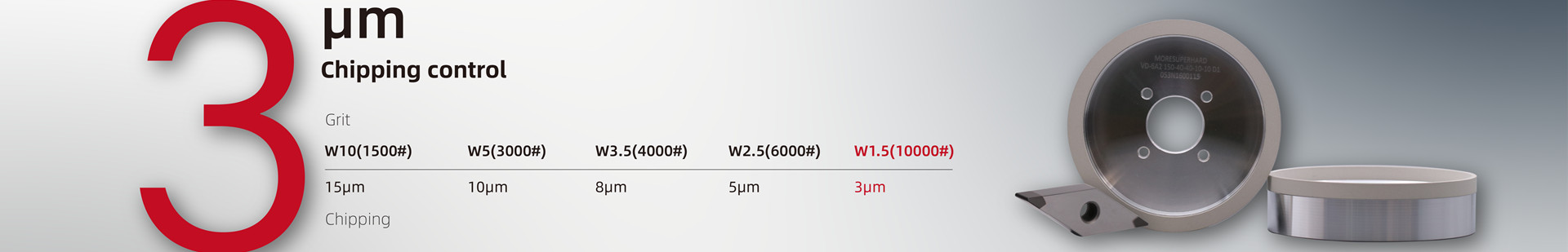

Wire dies grinding machine technical Parameters

| Input power | AC220 50/60HZ |

| Working frequency | 800w 20khz/300w 20khz |

| Total power | 800W/300W |

| Converter | Ceramic Pressed Plate |

| Die plate speed | 800W:110 rpm 300W:80rpm |

| Sweep mode | 60/min |

| Grinding range | 800W:1.3mm-15mm 300W:0.3mm-8mm |

Why choose moresuperhard wire dies grinding machine?

1.Integrated body, small footprint

2.Simple operation, automatic frequency scanning

3.The waveform is good, no running waves, no powder explosion,

4.The efficiency saves about half the time compared with general ultrasonic grinding machines.

5.The grinding machine has an adjustable angle of 30 degrees, which is more accurate than manual grinding and has a higher yield rate.

Guidance for using ultrasonic Wire Die Polishing Machine

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

"Hyperion invests in a U.S. diamond and CBN manufacturing center, driving advancements in the superhard materials industry. Moresuperhard ’s PCD laser cutting machine delivers high-precision, heat-free, and efficient cutting solutions for PCD tool manufacturers, enhancing productivity and competitiveness."

PDC cutters are widely used for gas,oli drilling,coal minning etc.Grinding procession will directly influence the quality od PCD cutter.Moresuperhard provide diamond grinding wheel for grinding different parts of pdc cutter like surface grinding,external grinding wheel ,double-sided grinding disc and centerless grinding wheel.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088