What is PCB?

PCB, or Printed Circuit Board, is the support for electronic components and the carrier for the electrical connection of electronic components. It adopts a multi-layer stacking design to compress the complex circuit layout into a compact space, saving the volume of the device and increasing the integration. PCB plays a vital role in modern electronic devices with its high reliability, low cost and convenience.

Common PCB Substrate Materials

There are many types of materials for PCB (Printed Circuit Board) substrates, mainly including the following:

FR-4 (Epoxy Glass Fiber Cloth Board)

The most common PCB substrate material, made of glass fiber woven cloth and epoxy resin, has good electrical insulation and mechanical strength. Suitable for most electronic products.

CEM-1 (Paper-based Composite Material)

Made of paper-based material combined with glass fiber cloth, it has good mechanical strength and heat resistance, relatively low cost, and is mainly used in home appliances and consumer electronics.

CEM-3 (Glass Fiber Paper-based Composite Material)

Similar to FR-4, but with less glass fiber content, lower cost, and slightly inferior performance. Usually used in low-cost electronic products.

Ceramic Substrate

Has good thermal conductivity and electrical properties, high temperature resistance, and is often used in high-frequency circuits and high-power applications such as LED lighting and microwave communications.

Metal Substrate

Usually an aluminum substrate with high thermal conductivity, used in applications requiring high heat dissipation performance, such as LED circuit boards and power electronic modules.

Polyimide (PI) substrate

Mainly used for flexible circuit boards (FPCs), it has good heat resistance and mechanical properties and is suitable for electronic products that need to be bent or folded.

PTFE (polytetrafluoroethylene) substrate

Also known as Teflon substrate, it has very low dielectric constant and loss factor and is suitable for high-frequency applications such as microwave circuits and radio frequency circuits.

Different materials have different electrical properties, mechanical strength and thermal conductivity, so when choosing PCB substrate materials, it is necessary to make comprehensive considerations based on specific application scenarios and requirements.

There are several difficulties in the grinding process of epoxy glass fiber cloth PCB substrate (FR-4):

Uneven material hardness and toughness

FR-4 substrate is made of glass fiber and epoxy resin. The glass fiber has a higher hardness and the epoxy resin is relatively soft, which leads to uneven grinding force during grinding. This material unevenness can easily cause uneven tool wear and affect the grinding quality.

Glass fiber reinforced materials are prone to wear of grinding tools

Glass fiber has high hardness and high abrasiveness. When grinding, it will cause serious wear on tools such as diamond grinding wheels and shorten the tool life. This increases processing costs and may lead to reduced processing accuracy.

Difficult heat management

The heat generated during the grinding process may cause local overheating of epoxy resin, causing burns or decomposition on the substrate surface, which in turn affects product performance. The thermal conductivity of glass fiber material is relatively poor, and uneven heat dissipation may aggravate this problem.

Material delamination and burr problems

During the grinding process, if the processing parameters are improper or the tool wear is severe, it may cause delamination of the PCB substrate and affect the structural integrity of the board. In addition, burrs are easily generated when grinding the glass fiber cloth layer, which affects the surface quality and requires subsequent treatment.

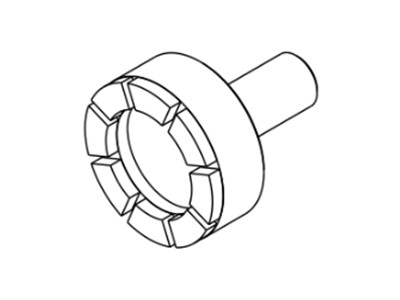

Grinding Case of Epoxy Glass PCB Substrate

PCB manufacturers mainly process epoxy composite materials, including SiO2 fibers and copper wires, and the workpiece materials have high requirements for processing tools. The customer uses a face milling machine for processing and hopes to find a suitable milling wheel to achieve high-quality surface finish. The customer's goal is to achieve a finish of 0.5μm, and they prefer to use air pressure for cooling and chip removal rather than traditional water cooling.

Based on the customer's needs, the Moresuperhard technical team recommended a ceramic bond diamond grinding wheel. After in-depth communication with the customer, it was finally recommended to first test the 320 and 1500 grit grinding wheels and gradually optimize the processing technology to achieve the customer's requirements for smoothness.

The customer tested the 320 and 1500 grit grinding wheels supplied by Moresuperhard using air pressure cooling. Preliminary test results showed that both grit sizes performed well in the customer’s process, especially in achieving the required surface finish.

<< :How to dressing cast iron lapping disc?

<< :Why Are PCD Cutting Tools Suitable for Machining CFRP Materials?

"Hyperion invests in a U.S. diamond and CBN manufacturing center, driving advancements in the superhard materials industry. Moresuperhard ’s PCD laser cutting machine delivers high-precision, heat-free, and efficient cutting solutions for PCD tool manufacturers, enhancing productivity and competitiveness."

PDC cutters are widely used for gas,oli drilling,coal minning etc.Grinding procession will directly influence the quality od PCD cutter.Moresuperhard provide diamond grinding wheel for grinding different parts of pdc cutter like surface grinding,external grinding wheel ,double-sided grinding disc and centerless grinding wheel.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088