Applications of single crystal diamond cutting tools

With the continuous development of the superhard tool market, single crystal diamond tools have become the main cutting tools in the field of ultra-precision machining. Compared with PCD tools, they can better achieve mirror processing, and the processed workpieces have extremely high precision and surface roughness, and have a long service life. Therefore, they are widely used in the field of ultra-precision machining. With the further development of national defense and cutting-edge technology, the quality requirements of single crystal diamond tools are getting higher and higher. It is particularly important to solve the problem of chipping and serration of the cutting edge when single crystal diamond tools are sharpened.

Moresuperhard grinding R&D for single diamond tools

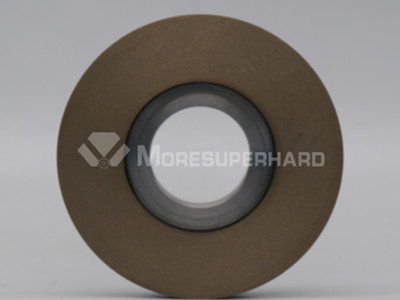

In view of the performance characteristics of diamond single crystal diamond tools and the quality requirements after processing, the R&D department of Moresuperhard strictly screens and controls the diamond crystal type and grade, improves the formula, adjusts the production process, and conducts multiple grinding experiments to develop rough grinding, semi-finishing grinding, fine grinding, and super-finishing ceramic bond and metal bond diamond grinding wheels with high stability and guaranteed grinding edge quality. Professionally solve the grinding problems of single crystal knives with high grinding efficiency, good retention, no edge collapse, stable grinding quality, guaranteed tip arc accuracy and long-lasting durability.

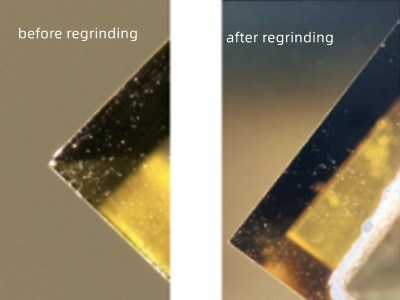

Grinding performance comparison

| Brand | Grinding machine | Grinding wheel type | Grain sizes | Machining allowance(mm) | Machining time(min) | Chipping |

| other brand | M50 cnc grinding machine | 6A2-150-15-10 | W5 |

0.2 |

15 | 0.015-0.02 |

| Moresuperhard | 12 | 0.005-0.007 |

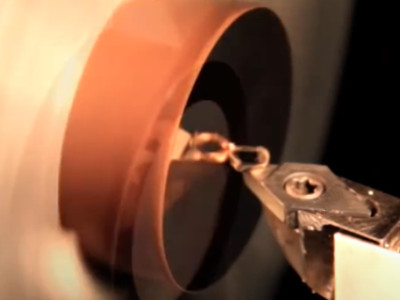

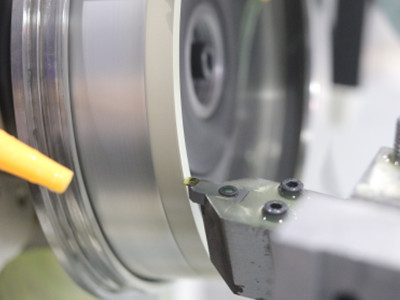

Ceramic diamond grinding wheel grinding SCD diamond tools

The rough and fine grinding wheels have been successfully matched with COBORN RG5 and RG9A, EWAG-RS15, FC-200D, M50cnc and other high-end diamond tool grinders at home and abroad, with particle sizes ranging from rough grinding W40 to super-fine grinding 10000#.

Rough grinding: W40, W20

Semi-finishing grinding: W10, W5

Fine grinding: W3.5, W2.5, W1.5

Grinding procession for single crystal diamond tools

You can use Moresuperhard ceramic-based W40 on a diamond tool grinder to rough grind and then use W20, or directly use W20 for rough grinding. While ensuring the controllable edge and increasing the service life, it can greatly improve the grinding efficiency; then use W10 for fine grinding, the edge can reach 0.01-0.013 (magnified 200 times), which fully meets the semi-fine grinding requirements of most customers, and the grinding force is also greatly improved. Subsequently, according to the grinding requirements, use ceramic-based or metal-based diamond grinding wheels for fine grinding, and the edge can be controlled at 0.002. If you have extremely high precision requirements for the edge, you can also use Moresuperhard PG series grinding wheels on the British PG3 or PG3B grinder or cast iron disc to fine grind the edge.

Why your grinding wheel cannot achieve grinding accuracy

In the specific grinding process, some customers may encounter the situation that the grinding wheel or diamond powder has very fine grains, but the grinding cannot meet the requirements. This may be mainly due to two reasons: one is that the edge is too large during rough grinding and cannot be repaired by fine grinding; the other is that large particles are mixed into the fine grinding or it is blocked, resulting in scratches on the workpiece.

Moresupehard has a strict raw material testing mechanism to ensure the stability of grinding wheel raw materials. Each batch of grinding wheels has strict quality inspection records to provide customers with stable high-quality grinding wheels. If you have any questions about single crystal diamond tool grinding, please feel free to consult.

A technical guide to selecting diamond grinding wheels for PDC cutter . Learn how ceramic and resin bond diamond wheels improve efficiency, precision, and tool life in oil & gas and mining applications.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088