Carbide rods manufacturer from India

One of our customers from India is mainly engaged in the production and processing of cemented carbide rods. Its workpiece material is cemented carbide, and its application areas include high-precision tool and mold manufacturing.

Problems that customers are currently facing:The grinding wheel has poor shape retention and is easy to deform

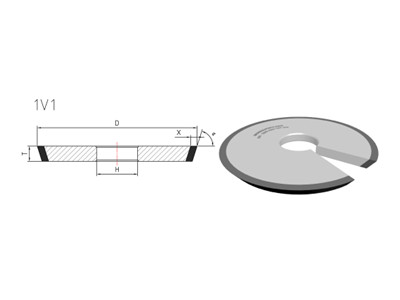

Recommand diamond grinding wheel specifications for chamfering carbide rods

1V1-D450-10T-10X-45V-203.2H-SD126

1V1-D450-15T-15X-45V-203.2H-SD126

Based on the customer's needs and applications, we initially recommended a metal bond grinding wheel. However, the customer reported that the outer diameter was too large and the thickness was too thin, and it needed to be improved to 3V1/14V1 type to enhance strength.

Scheme adjustment and quotation After further communication with the customer, we reached a consensus to thicken the total thickness of the grinding wheel to improve its strength and durability. However, when discussing the price, the customer thought the cost was too high, so he decided to adjust the grinding wheel size.

Finally, the customer agreed to change to the following size and asked for a price quote:

1V1-D350-T20-20W-10X-127H-AD126

Solution In order to meet the customer's requirements, we provided the following specific solutions:

Type: 1V1 grinding wheel Size: D350-T20-20W-10X-127H

Grit size: SD126

Binder type: resin-bonded diamond grinding wheel

Equipment compatibility: Applicable to the customer's existing cylindrical grinder to ensure the convenience of installation and operation.

Detailed installation and operation instructions are provided to ensure that customers can get started quickly.

Resin diamond grinding wheel Performance guarantee

By selecting the appropriate high-quality resin-bonded diamond grinding wheel, the shape retention and wear resistance of the grinding wheel during long-term high-intensity use are guaranteed.

During the processing, combined with the water cooling system, the workpiece temperature is effectively controlled to ensure the processing quality.

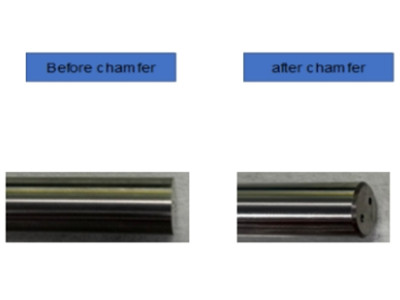

Diamond grinding wheel test results and feedback

After trying the new grinding wheel, the customer gave good feedback that the grinding wheel performed well in the chamfering of carbide rods, meeting their requirements for high precision and high efficiency. At the same time, by adjusting the size of the grinding wheel, the customer also achieved satisfactory results in cost control.

Choose Moresuperhard for good grinding solutions

Through in-depth communication and demand analysis with customers, we successfully provided them with a grinding wheel solution with excellent performance and controllable cost, further consolidating the cooperative relationship between the two parties. In the future, we will continue to be committed to providing customers with professional and precise processing solutions to meet their ever-changing needs.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Comparison of ns, ps, and fs lasers for PCD, carbide, and ceramic machining, and how Moresuperhard’s 5-axis laser PCD grinding machine delivers high-precision cold laser processing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088