PCD tools manufacturer from Vietnam

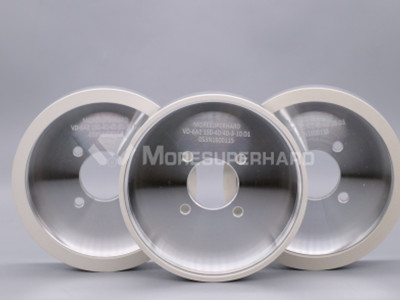

One of our customers from Vietnam uses a ceramic diamond grinding wheel with a specification of 6A2 D150H40T40W3X10 D1(W3.5) for processing PCD tools in the 3C industry. The customer reported that the two batches of 6 grinding wheels delivered recently were not durable during use, which was manifested in the rapid consumption of chips during use, the uneven surface of the abrasive layer, and the quality was different from before. The customer said that the grinding wheel automatically broke during use and could not be used and trimmed normally.

What causes diamond grinding wheels to change?

After receiving the customer's feedback, we immediately conducted a detailed inspection of the production process and formula of the two batches of grinding wheels. The results of the investigation showed that the production process and formula were exactly the same as before, with the only difference being that the thickness of this batch of diamond raw materials was slightly thinner. The production technicians speculated that it was this difference that caused the diamond to break and fall off easily during the grinding process, resulting in the phenomenon of rapid consumption of the grinding wheel.

Solutions for diamond grinding wheels rapid consumption

In order to completely solve this problem, we have taken the following measures: Hardness testing equipment upgrade: Previously, we found that narrow ring width grinding wheels could not be hardness tested, and all hardness was estimated based on the grinding wheel formula. Therefore, we decided to purchase a new hardness tester and indenter so that we can perform accurate hardness tests on narrow ring width grinding wheels in the future. Testing of new batches of grinding wheels: In response to this problem, we made two grinding wheels of different hardness for customers to test free of charge. The two grinding wheels differ in hardness in order to determine which hardness is more suitable for customers' use needs.

Customer feedback and adjustments: The customer tested the two test grinding wheels and finally chose a grinding wheel with a softer hardness of about HRC50. This hardness of grinding wheel performs relatively well during use and meets customer requirements.

Responsible for every pieces of grinding wheels

According to the customer's choice, we have arranged to re-produce grinding wheels that meet the hardness requirements of about HRC50 and deliver them to customers as soon as possible. We believe that through this improvement and adjustment, we can effectively solve the problems encountered by customers and improve the use effect and durability of grinding wheels.

Moresuperhard will continute improve our skills

This incident shows that even if the production process and formula are consistent, slight differences in raw materials may have a significant impact on product quality. We successfully solved the quality problem by upgrading hardness testing equipment and communicating closely with customers to ensure customer satisfaction. In future production, we will continue to maintain strict quality control and continuously optimize the process to provide higher quality products and services.

High-performance diamond composite cutters (PDC) for stone cutting saw blades. Learn key structural features, performance requirements, and selection guidelines for granite, marble, and quarry cutting applications.

Comparison of ns, ps, and fs lasers for PCD, carbide, and ceramic machining, and how Moresuperhard’s 5-axis laser PCD grinding machine delivers high-precision cold laser processing.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088