What is 20CrMnTiH?

20CrMnTiH steel is a type of steel that has been carburized to enhance its surface hardness and wear resistance. After carburizing, the surface of this steel has high hardness and wear resistance, while the core still maintains good toughness and plasticity. Case-hardening steel is widely used in mechanical parts that require high surface hardness and good toughness, such as gears, shafts, cams, rolling bearings and other transmission parts.

Customer requirements for SG grinding wheel

A mechanical manufacturing company mainly produces high-precision mechanical parts, including shafts, piston parts and various special parts of automobiles and aircraft, especially gears, gear rings, gear shafts and crossheads. The company recently faced the challenge of improving processing efficiency and quality, especially when processing carburized steel 20CrMnTiH parts, traditional grinding wheels are difficult to meet the grinding requirements of high-hardness materials.

20CrMnTiH Grinding Requirements

The customer needs an efficient and durable grinding wheel to grind carburized steel 20CrMnTiH. The grinding wheel is required to reduce heat generation while maintaining high hardness and wear resistance, avoid burns on the workpiece surface, and ensure that the depth of the carburized layer after grinding meets the design requirements.

Solution for grinding gear steel

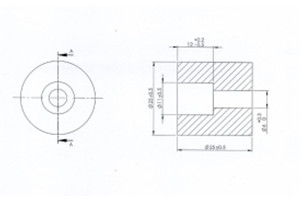

After detailed analysis and technical evaluation, it is recommended that customers use SG general grinding wheels with the following specifications: Size: D25xT25xH6xP11xF12mm Grit: 80# Hardness: HRC 58-63 Heat treatment: carburizing heat treatment Effective carburizing layer depth: 1.2-1.6mm before grinding, 1.0-1.4mm after grinding

SG grinding wheel testing result

Grinding effect: The carburizing layer depth after grinding is 1.0-1.4mm, which meets the design requirements. The surface finish is high, without obvious burns and thermal damage.

Processing efficiency: SG grinding wheels have good self-sharpening and high grinding efficiency, which reduces the frequency of downtime for grinding wheel replacement and improves production efficiency.

Cost control: Due to the high wear resistance and long service life of SG grinding wheels, customers have a significant reduction in grinding wheel replacement and grinding costs.

Customer feedback for Moresuperhard SG grinding wheel

Customers are very satisfied with the performance of SG grinding wheels, especially the high efficiency, stability and durability when grinding carburized steel 20CrMnTiH. By using SG grinding wheels, customers not only improve product quality, but also significantly improve production efficiency and reduce processing costs.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088