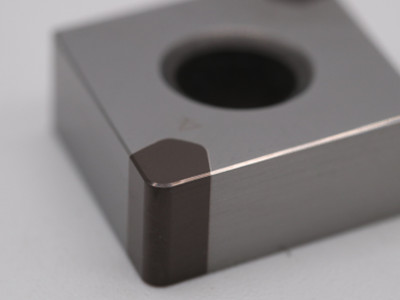

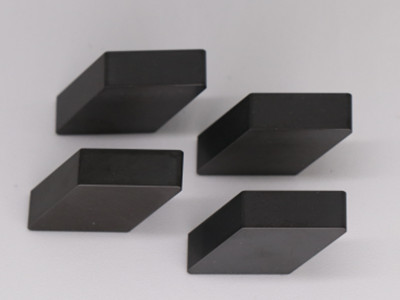

What is CBN inserts?

CBN inserts are advanced cutting tools designed for demanding machining operations involving hard and abrasive materials. Their superior hardness, heat resistance, and chemical stability make them an excellent choice for applications requiring high precision, durability, and efficiency.

What are CBN inserts used for?

CBN inserts are commonly used in industries where high performance and precision are required, including:

Hard Turning: CBN inserts are ideal for hard turning operations on hardened steels (typically above 45 HRC), where traditional carbide tools would fail quickly.

Abrasive Materials: They are effective for machining abrasive materials such as cast irons, sintered metals, and hardened tool steels.

Finishing Operations: Due to their ability to provide a superior surface finish, CBN inserts are often used in finishing operations where surface quality is critical.

High-Temperature Alloys: These inserts can be used to machine high-temperature alloys used in aerospace and automotive industries.

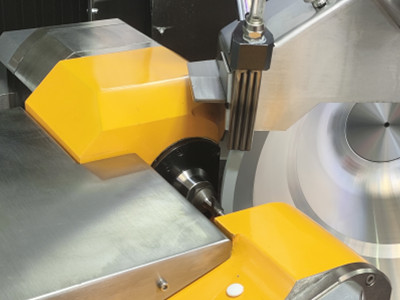

What kind of grinding wheels are suitable for grinding CBN inserts?

High hardness and wear resistance: Diamond is the hardest material in nature, with extremely high hardness and wear resistance, and can effectively grind CBN materials. The hardness and wear resistance of the grinding wheel directly affect the grinding efficiency and the service life of the grinding wheel.

Good bonding strength: The diamond particles in the grinding wheel need to be firmly fixed together by a binder. The type and strength of the binder determine the durability and grinding performance of the grinding wheel. Commonly used binders include metal binders, resin binders, and vitrified binders.

Good thermal conductivity: A large amount of heat is generated during the grinding process. If the heat cannot be dissipated in time, the temperature of the grinding wheel and the blade will rise, affecting the grinding effect and the performance of the blade. The diamond grinding wheel should have good thermal conductivity for rapid heat dissipation.

High chemical stability: The diamond grinding wheel should have good chemical stability under high temperature and high pressure, and it is not easy to react chemically with the CBN blade or coolant to maintain the performance of the grinding wheel and blade.

Good shape retention: The grinding wheel should maintain a stable shape and size during the grinding process to ensure grinding accuracy and consistency. This is especially important for high-precision grinding. Uniform abrasive distribution: The diamond particles in the grinding wheel should be evenly distributed to ensure uniform wear of the abrasive during grinding and provide a stable grinding effect.

Resin diamond grinding wheel &Ceramic diamond grinding wheel

Resin Bond Diamond Grinding Wheel:

Features: Resin bond grinding wheels have good self-sharpening properties. During the grinding process, the grinding wheel can continuously self-dress and keep sharp. They are generally suitable for applications with low to medium grinding forces.

Advantages: Able to provide good surface finish, suitable for fine grinding; relatively low price.

Disadvantages: Poor heat resistance, easy to soften at high temperature, suitable for low temperature grinding environment.

Vitrified Bond Diamond Grinding Wheel:

Features: Vitrified Bond grinding wheels have high hardness and brittleness, suitable for high-precision grinding. They usually maintain good performance at high temperatures.

Advantages: Good self-sharpening, low dressing frequency, suitable for high-precision and high-efficiency grinding; good heat resistance, suitable for high-temperature grinding environment.

Disadvantages: Higher price

Moresuperhard has rich experiences in grinding CBN cutting tools.Most of oue customers use vitrified bond diamond grinding wheel for grinding cbn inserts.But resin diamond grinding wheels are suitable for grinding CBN saw blades.

6A2 diamond cup grinding wheel and peripheral grinding wheels are usually used for grinding CBN tools.Moresuperhard provide customized specifications and grains diamond grinding wheel.Welcom your inquire.

Comparison of ns, ps, and fs lasers for PCD, carbide, and ceramic machining, and how Moresuperhard’s 5-axis laser PCD grinding machine delivers high-precision cold laser processing.

Learn how to choose the right PDC cutters for deep and hard rock formations. Explore diamond thickness, thermal stability, impact toughness, cutter geometry, and bit design.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088