What is ceramic bonding tools?

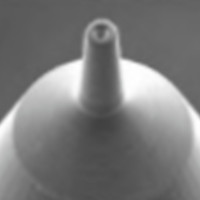

Ceramic bonding tools, also known as ceramic capillary or ceramic nozzle, is an axisymmetric ceramic tool with a vertical hole, belonging to a precision microstructure ceramic component. In application, ceramic bonding tool is used as a wire bonding tool in the wire bonding process, and can be used for bonding and packaging of thyristor, surface acoustic wave, LED, diode, triode, IC chip and other circuits.

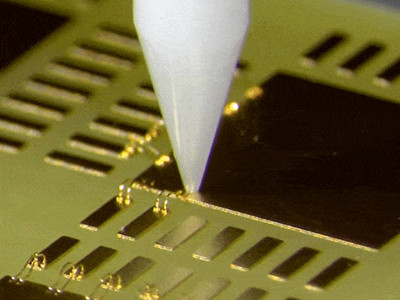

The following figure shows the process of wire bonding. By using thin metal wires (copper, gold, etc.) and heat, pressure, and ultrasonic energy, the metal wires can be tightly welded to the substrate pads, thereby achieving electrical interconnection between the chip and the substrate and information exchange between chips.

Ceramic bonding tools materials

The main manufacturing material of ceramic bonding tool is alumina. High-density fine-grained alumina ceramics have strong wear resistance and oxidation resistance, and are easy to clean. After adding other ingredients, they are fired in an atmosphere furnace to above 1600°C, and then finely processed to form a long-life consumable material used in the field of microelectronics.

Classification of ceramic bonding tools

Since the use of ceramic bonding tools can affect the quality of chips and the stability of production, the selection of ceramic splitters is very important in the field of microelectronics.

Currently available ceramic splitters include capillary bonding tools used in ball bonding and wedge bonding tools used in wedge bonding.There are fundamental differences between the two ceramic splitters, as shown in the table below.

Different types naturally have different bonding methods. The general arc height of ball bonding is 150μm, the arc length should be less than 100 times the wire diameter, and the bonding head size should not exceed 3/4 of the pad size. The ball size is generally 2 to 3 times the wire diameter, and the fine pitch is about 1.5 times; for wedge bonding, the pad size must support the bonding point and tail end of the factory, the pad long axis must be in the wire routing direction, and the pad spacing is suitable for a fixed bonding spacing.

Diamond grinding wheels for ceramic bonding tools

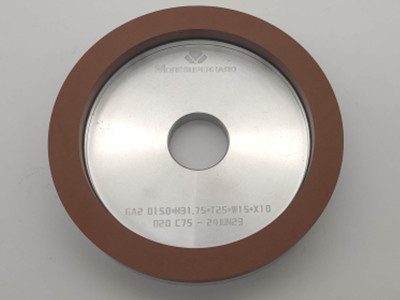

Resin bond diamond grinding wheel:

Suitable for precision grinding and polishing stages, especially when high surface quality and complex shape processing are required.

Suitable for harder but not too brittle ceramic materials.

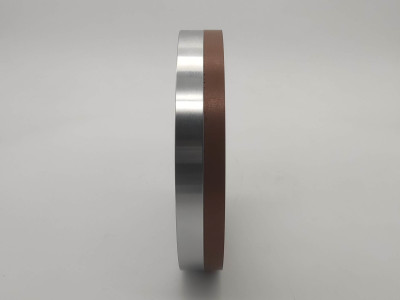

Metal bond diamond grinding wheel:

Suitable for rough grinding and semi-finishing grinding stages, especially when high material removal rate and long grinding wheel life are required.

Suitable for ceramic materials with high hardness and high toughness.

Choose suitable grind wheel grain sizes for grinding ceramic bonding tools

For grinding of ceramic bonding tools, it is recommended to use diamond grinding wheels and select appropriate grits according to different grinding stages.

Rough grinding: Use diamond grinding wheels with coarse grits, such as D46 or D76.

Semi-fine grinding: Use diamond grinding wheels with medium grits, such as D20 or D30.

Fine grinding and polishing: Use diamond grinding wheels with fine grits, such as D7 or D10.

By selecting appropriate grinding wheels and optimizing grinding parameters, the processing quality and efficiency of ceramic bonding tools can be effectively improved.Moresuperhard recommand resin and metal bond diamond grinding wheel for sharpening precision ceramic bonding tools.And Moresuperhard provide customized grinding wheels according to your grinding machine.Welcome your enquire.

PCD tools offer excellent hardness and wear resistance for machining difficult materials, but grinding them poses unique challenges. This article explores common issues such as chipping, high surface roughness, dimensional deviations, burning, and grinding wheel wear. Learn practical solutions to optimize grinding parameters, wheel selection, and machine accuracy to improve tool life and reduce costs.

Discover how our 3A1 ceramic diamond wheel helped a client achieve ultra-precise PCD reamer grinding. Learn how adjusting bond hardness and grit size resolved issues with carbide shank grinding for better edge quality and stability.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088