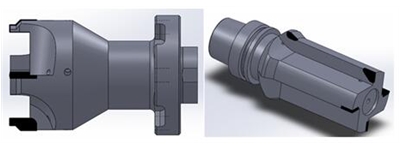

Polycrystalline diamond (PCD) tool for automotive piston

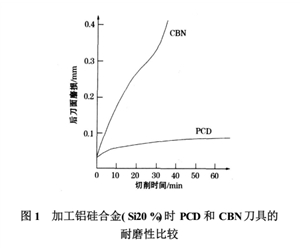

In order to improve the performance of the engine, the piston material is changed from low silicon aluminum alloy to medium silicon aluminum alloy, and even high silicon aluminum alloy.And the PCD tools with excellent characteristics, it widely used in processing aluminum alloy, especially for high silicon aluminum alloy.

The hardness and wear resistance of high silicon aluminum alloy are higher than other aluminum alloys. When normal cutting tools alternately cut soft aluminum and hard silicon particles, the tool is also easy to produce debris, so the processing accuracy and surface roughness will deteriorate.

In order to avoid chip deposition and hardening, the blade must be sharp and the blade surface must be smooth, and the PCD cutter meets these requirements.

Using:

1.Although PCD tools has extremely high hardness, its toughness is not as good as that of cemented carbide and much lower than that of high-speed steel, so the main failure form of PCD tools is cutting edge.

Cutting edge collapse is usually caused by vibration in machining. It is helpful to reduce vibration to reduce tool overhang and improve rigidity of machine tool. High rigidity machine tool is necessary condition for PCD tool, most using on CNC machine for fine processing of silicon aluminum piston.

2.

3.PCD tools can for surface machining, hole machining, ring groove machining. For surface machining or boring of aluminum piston with PCD tool, coolant is usually not required, while for semi-closed machining with ring groove, smooth chip removal and cooling and lubrication of cutting edge are required.

<< Prev Article:Precision grinding of super-hard abrasive wheels

<< Next Article:PCD tools for Graphite precision turning

LATEST NEWS

-

20 August 2020

PCD tools grinding wheel

Vitrified bond diamond grinding wheels possess pretty high a...

-

07 May 2020

Precision hole machining

Our company mainly develops a new making holes’ method for P...

CONTACT US

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 15617330220