The necessity for wheel dressing

Grinding wheel dressing plays a vital role in high-speed and high-efficiency grinding, precision ultra-precision grinding, and form grinding. In the grinding process, the interaction between the grinding wheel and the workpiece surface is the main reason, and the grinding wheel gradually becomes dull as the grinding progresses, which is difficult to grind effectively. In order to ensure the grinding quality and precision, it is necessary to dress the grinding wheel regularly.

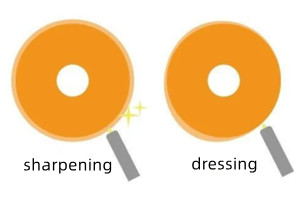

Grinding wheel dressing is mainly divided into two aspects: dressing and sharpening. dressing refers to the operation of processing the contour and shape of the grinding wheel, compensating for the shape loss caused by the grinding wheel in use, and processing it into a specified shape suitable for the shape of the workpiece. Sharpening refers to the adjustment of the surface of the grinding wheel to expose new abrasives and sharp points to form a cutting edge on the dulled abrasive grains.

Difficulties in Dressing Diamond Grinding Wheels

On the one hand, the superhard abrasive has extremely high mechanical strength and is extremely difficult to break. Moreover, the abrasive grains are embedded in the binder to form a dense structure of soft and hard combination. It is difficult to use the traditional dressing method to mix the binder and the grinding wheel like a normal grinding wheel. The grains are repaired at the same time. Therefore, the shaping efficiency is low, and the shaping is difficult.

On the other hand, because the superhard abrasive has high surface binding energy, it is not easy to form a high-strength bond with the binder. Therefore, the abrasive grains are not easy to be partially broken and repaired by the abrasive grains during the dressing process. It is difficult to achieve very precise dressing accuracy in the dressing result of the grinding wheel.

Common methods of diamond grinding wheel dressing

Turning method (single point diamond pen dressing), grinding dressing method, diamond roller dressing method, electrolytic and electric spark dressing method

dressing solution for diamond grinding wheel from moresuperhard

|

Dressing wheel |

Peripheral grinding wheel |

Application |

||||

|

meterial |

characteristic

|

Grain size |

Grinding wheel bond

|

Grinding wheel grain zize |

Grinding method

|

Inscert meterials |

|

Ceramic Alumina Dressing Wheel

|

- Lower hardness - Softer than silicon carbide grinding wheel - no damage to diamond particles during sharpening

- First choice for sharping peripheral grinding wheels

|

120# |

resin |

≥320# |

Peripheral grinding wheel |

Carbide ceramics

cermet |

|

mental |

>600# |

Peripheral grinding wheel |

Carbide

ceramics |

|||

|

vitrified |

>240# |

Peripheral grinding wheel |

carbide

ceramics |

|||

|

320# |

resin |

<320# |

Peripheral grinding wheel |

carbide ceramics cermet

|

||

|

mental |

≤600# |

Peripheral grinding wheel |

carbide,ceramics |

|||

|

vitrified |

≤240# |

Peripheral grinding wheel |

PCBN,PCD |

|||

|

500# |

vitrified |

≤1500# |

Peripheral grinding wheel |

PCBN,PCD |

||

|

Ceramic Silicon Carbide Dressing Wheels

|

- High hardness

- suitable for dressing grinding wheels.

|

80# |

resin |

>120# |

Top and bottom |

carbide,ceramics,cermet |

|

mental |

>150# |

Top and bottom |

carbide,ceramics |

|||

|

200# |

resin |

≥240# |

Peripheral grinding wheel |

carbide,ceramics,cermet |

||

|

mental |

≥320# |

Peripheral grinding wheel |

carbide,ceramics |

|||

The above dressing wheel selection methods are for reference only.

Welcome to consult moresuperhard,we will choose a more suitable dressing plan according to your actual diamongd peripheral grinding wheel.

Comparison of ns, ps, and fs lasers for PCD, carbide, and ceramic machining, and how Moresuperhard’s 5-axis laser PCD grinding machine delivers high-precision cold laser processing.

Learn how to choose the right PDC cutters for deep and hard rock formations. Explore diamond thickness, thermal stability, impact toughness, cutter geometry, and bit design.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088