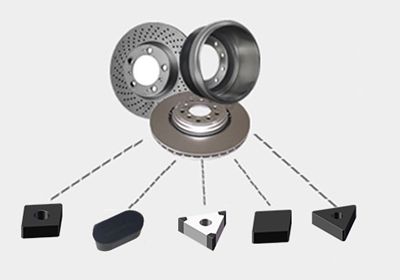

Automotive brake disc has high requirements for finish and processing efficiency, usually the surface roughness is required to be Ra1.6, the circumference thickness difference between the two braking surfaces is usually required to be controlled within the range of 0.009mm, parallelism is required to be within 0.04mm, run-out is required to be within the error range of 0.025mm, and these shape and position tolerances are guaranteed by finishing. The traditional grinding technology has been difficult to meet the market demand for shape and position tolerance turning. PCBN tool has extremely high hardness and wear resistance, and shows great advantages in processing brake disc. It can not only obtain satisfactory surface processing quality (surface roughness Ra1.6), improve production efficiency, but also reduce the processing cost of single piece, which has significant economic benefits.

Materials and Properties of Brake Disc

The material of car brake disc is generally gray cast iron, and the common material is HT250, with a minimum tensile strength of 250MPa and a hardness of 209HB, good strength, wear resistance and heat resistance, and good shock absorption. However, the brake disc has poor ductility and is a short chip material, usually with low cutting force. In addition, due to the uneven distribution of graphite, the hardness of the brake disc changes, which will lead to PCBN cutter processing fluctuations, even collapse phenomenon, and reduce the processing efficiency of the brake disc. In addition, non-plastic material in gray cast iron will accelerate the wear of the tool, so the PCBN tool is required to have high wear resistance. The typical chemical composition of HT250 is shown in Table 1.

Table 1 the chemical composition of HT250

|

C/% |

Si/% |

Mn/% |

S/% |

P/% |

|

3.16-3.30 |

1.79-1.93 |

0.89-1.04 |

0.094-0.125 |

0.120-0.170 |

Notes of PCBN tools during machining

First of all, we should pay attention to the rigidity of the whole process system of the machine tool, fixture and tool. The jig itself should have enough strength and rigidity, and the extended length of the cutter head should be as short as possible to avoid the vibration of the cutter during the processing.

When installing the tool, the tip should be aligned with the workpiece center to avoid vibration when the tool is too high or too low。

Different processing procedures, to choose a reasonable processing parameters, too high or too low will not only affect the production efficiency, but also reduce the service life of the tool.

Cases of Brake disc machining

①Coarse turning of brake surface and end face, take the diameter of the brake disc D=278mm as an example, the machining parameters V=650m/min, AP =2.5mm, f=0.5mm/r

|

Procedure |

Machining Position |

Inserts Type |

Inserts Material |

|

① |

Cylindrical chamfering |

SNGN120712 |

CBN |

|

② |

Inner Hole Chamfer |

SNGN120712 |

CBN |

|

③ |

Coarse turning of brake surface |

CNGN120712 |

CBN |

|

④ |

Coarse turning of brake upper end face |

SNGN120712 |

CBN |

②Coarse turning of inner endface and bottom face, Take the diameter of the brake disc D=278mm as an example, and the machining parameters V=650m/min, AP =2.5mm, f=0.5mm/r

|

Procedure |

Machining Position |

Inserts Type |

Inserts Material |

|

① |

Cylindrical turning |

SNGN120712 |

CBN |

|

② |

Chamfering |

SNGN120712 |

CBN |

|

③

|

Coarse turning of brake bottom face |

SNGN120712 |

CBN |

|

Coarse turning of brake inner end face |

CNGN120712 |

CBN |

|

|

④ |

Arc turning |

CNGN120712 |

CBN |

|

⑤ |

Turning inside hole |

CNGN120712 |

CBN |

|

chamfering and turning small bore |

SNGN120712 |

CBN |

|

|

⑥ |

Coarse turning of brake bottom face |

SNGN120712 |

CBN |

③Fine turning, take the diameter of the brake disc D=278mm as an example, the machining parameters V=500m/min, AP =0.1-0.2mm, f=0.25mm/r

|

Procedure |

Machining Position |

Inserts Type |

Inserts Material |

|

① |

Coarse grinding of small hole |

SNGN090408 |

CBN |

|

② |

Finish turning of inner end face |

TNGA090408 |

CBN |

|

③ |

Coarse grinding of brake upper end face |

SNGN090408 |

CBN |

|

Finish grinding of brake bottom end face |

SNGN090408 |

CBN |

If you want to know more about PCBN Tools in Machining Brake Disc area, feel free to contact us.

Diamond wafers have great potential in high-end fields such as quantum computing, microwave power devices, and semiconductor lasers due to their ultra-high hardness, excellent thermal conductivity, and wide bandgap properties.

Discover how our ceramic diamond grinding wheels enhance efficiency and precision in PCD chrome-plated workpiece machining. With optimized grinding processes, extended tool life, and improved surface finish, our solutions help manufacturers achieve higher productivity and lower costs.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088