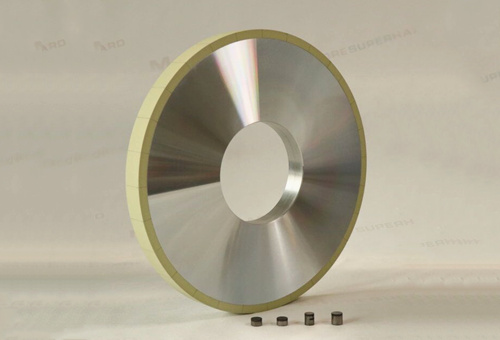

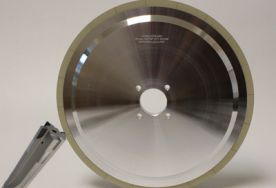

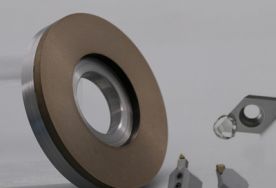

Vitrified diamond wheel for cylindrical grinding pdc

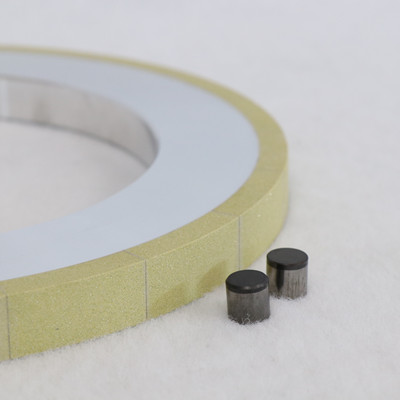

Workpiece: PDC, Polycrystall diamond compact

Bond: vitrified bond, resin bond

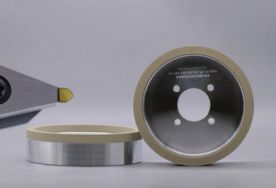

Customer Evaluation

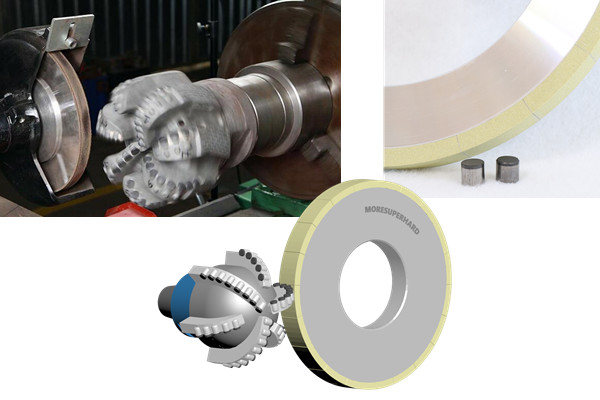

"Good news the third trial wheel performed successfully we completed four blocks with 2.5mm removal of Diamond cutters, eight grinding passes in total, the operator was more than happy with the quality of the finish”. - from UK client

" It was very similar to 3M's grinding wheel but our price is a little better so it makes better sense". - from UK client

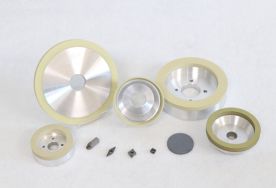

Applications of diamond cylindrical wheel

Diamond wheels are widely used in Oil and Gas drill, mining drill industry. Cylindrical grinding wheel can be used for grinding PCD bit teeth and many other parts. Vitrified diamond Cylindrical grinding wheel for rough grinding the cylinder of polycrystalline diamond compacts (PDC cutter). Compared with resin diamond grinding wheel, Moresuperhard grinding wheels lead to 35% grinding cost reduced, 40% grinding time of each PDC saved, and the size precision of PDC improved.

PDC (polycrystalline diamond compact) is a composite material sintered by diamond powder and carbide substrate under high temperature and high pressure. The abrasion loss reach 13-40 million, that are extremely difficult to process. Vitrified diamond Cylindrical grinding wheel for rough grinding the cylinder of Polycrystalline Diamond Compacts (PDC cutter).

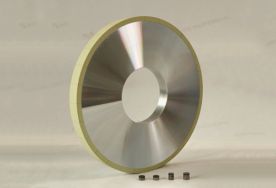

Features of vitrified diamond grinding wheel

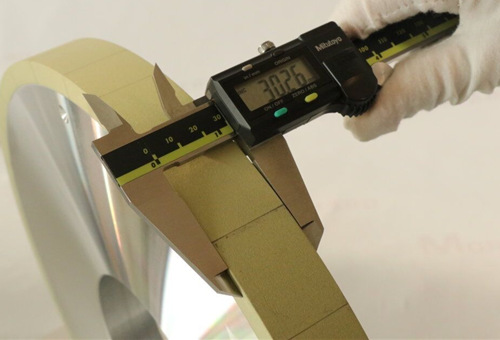

1. Vitrified diamond grinding wheel is 3 times the grinding efficiency of the resin diamond grinding wheel.

2. Vitrified diamond grinding wheel do not need to be dressed no longer, in addition to the in the entire grinding process, in addition to the grinding wheel surface sharpen first. Resin diamond grinding wheel must be trimmed 7 to 12 times, or do not grind the workpiece.

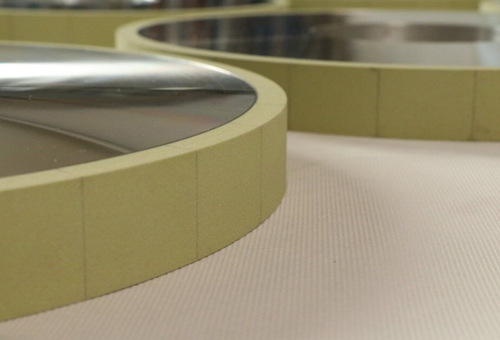

3. The side of PDC which is ground by vitrified diamond grinding wheel project into rectangular, the two surface size is the same. The dressing time will reduce when grinding, and the workpiece processing accuracy is high, and the gloss is high. vitrified diamond grinding has large overall elastic modulus, good rigidity, heat resistance, will not cause cutter back-off phenomenon.

4. The workpiece finish is better than that of resin diamond grinding wheel process. The products which are processed by vitrified diamond grinding wheel can reach the mirror gloss, coarse grinding and fine grinding as one process will be completed.

5. When vitrified diamond grinding wheel grinding PDC product, it has high grinding efficiency, less dressing time, high accuracy of workpiece processing size, good finish, vitrified diamond grinding wheel is the ideal of grinding PDC.

6. The centerless vitrified diamond grinding wheel is suitable for finish grinding polycrystalline diamond compacts(PDC).

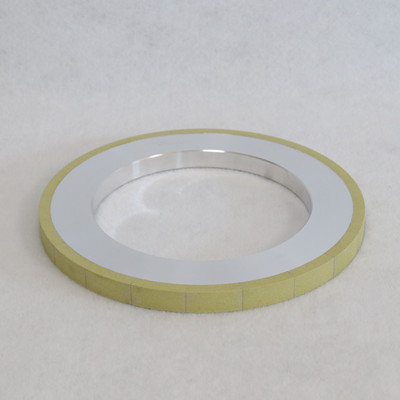

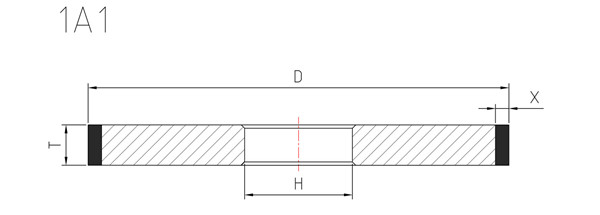

Specification Of External Cylindrical Diamond Wheel

|

Model |

D (mm) |

T (mm) |

H (mm) |

X(mm) |

|

1A1

diamond wheel |

350 |

40 |

127 |

10 |

|

400 |

40 50 |

203 |

10 |

|

|

400 |

40 50 |

305 |

10 |

|

|

Other size can be designed, according to the customers’ requirement |

||||

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088