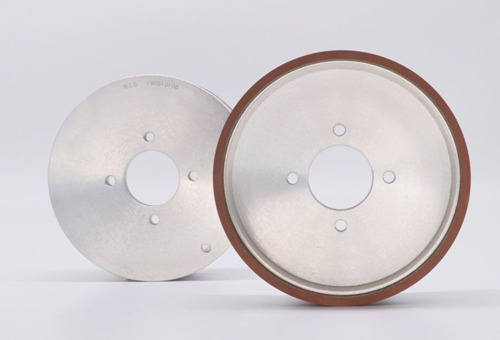

- Diamond Cup wheels for grinding PCD, PCBN, Carbide and Ceramic cutting tools

- Bonded: vitrified bond, resin bond and metal bond

- Grinding CBN tools, resin bond diamond grinding wheel is mostly used

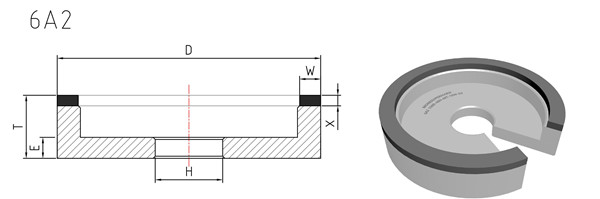

- Types : 6a2, 6a2C, 6a2H

Applications of diamond cup grinding wheels

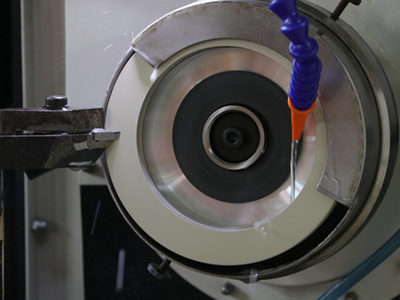

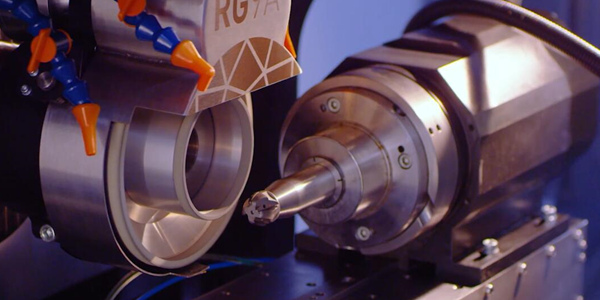

Diamond grinding wheels are used for grinding PCD cutting tools, PCBN cutting tools, CVD tools, MCD tools, milling cutter, reamer, drill and regrinding. Diamond cup grinding wheel also is used for grinding PCD and PCBN tools, glass, ceramics, quarts, semi-conductors, and other non-metallic materials.

* When grinding CBN tools, resin bond diamond grinding wheel is mostly used. If the machining tolerance is big, you can use 140/170 for rough grinding,then use230/270,W35,W28 for fine grinding. If you want to save cost & time you can choose W35 for whole grinding.

PCD and CBN cutting tools are widely used in metal cutting and processing nowadays."More Super Hard Products" devotes to offer an efficiency and economic solution in PCD and CBN cutting tools grinding

Advantages of diamond cup grinding wheel

- Precision control of geometric tolerance

- Good self-sharpening

- High working efficiency

- Good elastic, good polishing performance

- Superior insert edge quality

The specification of diamond cup grinding wheel

|

Model |

D(mm) |

T (mm) |

H (mm) |

W (mm) |

X (mm) |

|

6A2 |

150 |

40 |

32 40 |

3 5 10 15 20 |

10 |

|

125 |

40 |

32 40 |

3 5 10 |

10 |

|

|

100 |

40 |

32 40 |

3 5 10 20 |

10 |

|

|

Grit: 325/400, W40 (500#), W28 (600#), W20 (800#), W10 (1500#), W5 (3000#), W3 (5000#) |

|||||

Suitable PCD Grinding Machines: Coborn, Ewag, Anca, Farman, Mytech

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088