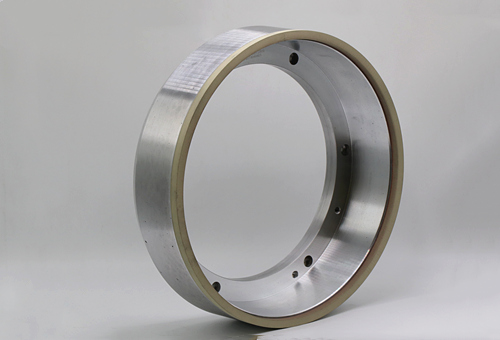

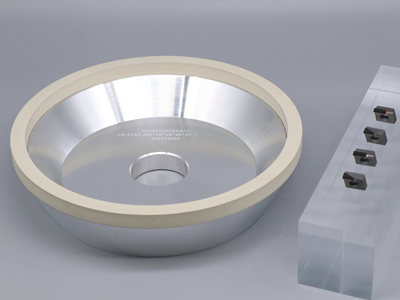

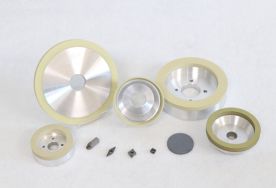

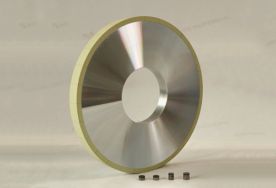

Peripheral grinding wheels for machining Indexable Inserts

- Bonds: resinous, hybrid, vitrified

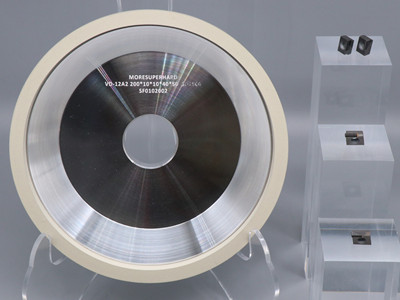

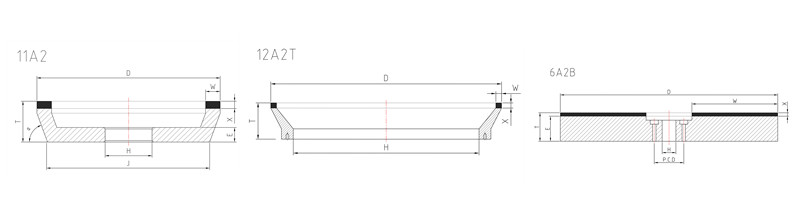

- Shape: 6A2T, 6A2H, 11A2, 11A2B, 2A2T, 11A2H, 12A2T, 15A2T

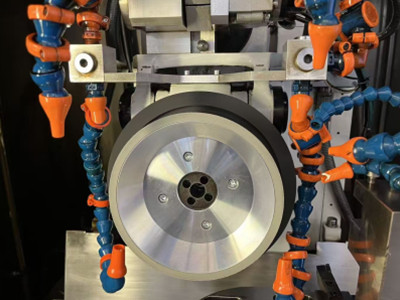

- Grinding Machines: Agathon, Ewag, HAAS, Waida, Wendt, Coborn, etc

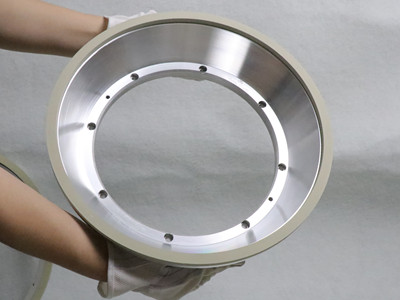

Peripheral Diamond Grinding wheels for indexable inserts, must be of a high level of geometrical accuracy, with ability of significant material removal. We are able to produce various types wheels to suit all popular machines, such as WENDT, WAIDA, AGATHON, EWAG, COBORN, etc. Manufacture of grinding wheels for indexable inserts is one of the key focus areas. Moresuperhard can offer customers solution that increase the value of their grinding processes in the area of indexable inserts. After intensive analysis of the process, Moresuperhard develops custom-made tool solutions for you for grinding highly complex geometries in ultra-hard materials like carbides, PCD, CBN, ceramics, or cermets.

Moresuperhard diamond wheels for insert periphery grinding

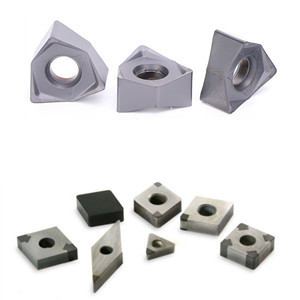

- Mainly used for precision edge peripheral grinding of indexable inserts, tungsten carbide inserts, ceramic inserts, CBN inserts

- Workpiece materials: tungsten carbide, ceramics, cermet, PCD and PCBN inserts

- Grinding periphery, T-lands, chip breakersand other geometries of tungsten carbide, ceramic, CBN or PCD inserts

How to choose the right peripheral grinding wheel

1. Grinding PCD, PCBN inserts. Preferred vitrified diamond grinding wheel for grinding PCD

2. Peripheral grinding of tungsten carbide and cermet cutting inserts. Resin diamond wheels for grinding carbide inserts and ceramic inserts.

Specifications of peripheral grinding wheel for indexable inserts

|

Machining Material |

Bond type |

Shape |

Size |

Grinding machine |

||||

|

D |

W |

X |

T |

H |

||||

|

Tungsten carbide

ceramic inserts |

Resinous

Hybrid |

12A2T |

350 |

6 8 10 12 15 |

6 |

27 |

300 |

Agathon 350/400

Wendt |

|

400 |

6 8 10 12 15 |

6 |

28 |

340 |

||||

|

2A2M |

250 |

6 8 10 |

6 |

42 |

215 |

|||

|

CBN

PCD inserts |

Vitrified

Resin |

11A2B |

200 |

6 8 10 12

|

6 10 |

45 50

60 |

50

60 |

Waida Ewag

Coborn |

|

6A2B |

350 |

10 |

10 |

92 |

260 |

|||

|

Special size peripheral grinding wheels can be design, according to your requirement. |

||||||||

Dressing method for peripheral grinding wheel

A careful selection of an aluminum oxide and silicon carbide dressing tools are the perfect supplement to Moresuperhard grinding wheels that are optimized for the application. With the right bond and grain size, you can obtain the best possible sharpening and grinding results using our dressing wheels.

|

Dressing wheel |

Peripheral grinding wheel |

Application |

||||

|

Type |

Features |

Grit |

Bond of grinding wheel |

Grit |

Grinding method |

Material of inserts |

|

Ceramic aluminum oxide dressing wheel

|

Lower hardness, softer than silicon carbide grinding wheel. When dressing, it will not cause damage to diamond particles. It is the ideal choice for dressing peripheral grinding wheel.

|

120# |

Resin |

≥320# |

Peripheral grinding |

Cemented carbide, ceramic, cermet |

|

Metal |

>600# |

Peripheral grinding |

Cemented carbide,ceramic | |||

|

Ceramic |

>240# |

Peripheral grinding |

Cemented carbide,ceramic | |||

|

320# |

Resin |

<320# |

Peripheral grinding |

Cemented carbide, ceramic, cermet |

||

|

Metal |

≤600# |

Peripheral grinding |

Cemented carbide,ceramic |

|||

|

Ceramic |

≤240# |

Peripheral grinding |

PCBN,PCD |

|||

|

500# |

Ceramic |

≤1500# |

Peripheral grinding |

PCBN,PCD |

||

|

Ceramic Sic dressing wheel

|

High hardness, Suitable for dressing the profile of grinding wheel

|

80# |

Resin |

>120# |

Top and back face |

Cemented carbide, ceramic, cermet |

|

Metal |

>150# |

Top and back face |

Cemented carbide, ceramic |

|||

|

200# |

Resin |

≥240# |

Peripheral grinding |

Cemented carbide, ceramic, cermet |

||

|

Metal |

≥320# |

Peripheral grinding |

Cemented carbide, ceramic |

|||

Moresuperhard grinding wheels are usable on grinding machines from all world's prime producers like: Agathon, EWAG, HAAS, Waida, Wendt, etc.

- AGATHON

400 Series: 400 PENTA, 400COMBI, 400SEMI, 400PERI.

350 Series: 350T B, 350COMBI

250 Series: PA250

AGATHON 400 PENTA 5-axis insert grinder is a fully automatic grinding center of the latest generation providing increased efficiency for insert production, the wheels used on AGATON are up to 400mm diameter. Which can grind most tool geometries with flexible clamping system. AGATHON laser machine can reduce the PCD processing time when make tool insert rough cutting, which can take place the rough grinding sometimes.

- WENDT

400 Series: WAC715, WAC735

350 Series: WAM336

- WAIDA

AP460E

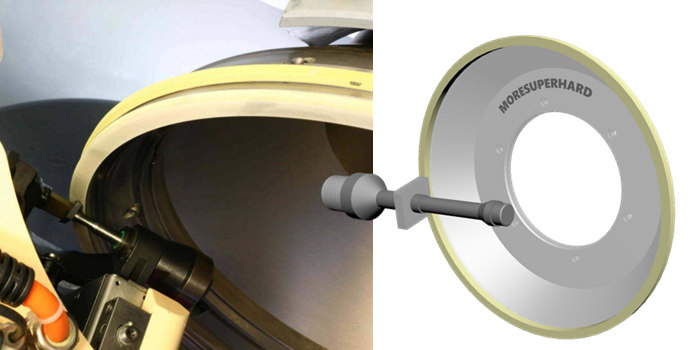

- EWAG EWAMATIC LINEAR

The grinding wheel used on EWAG, diameters of up to 500mm, can reduce 50% produce than their traditional grinding machine which use 250mm diameter wheels. The EWAMATIC LINEAR is a high-precision grinding machine which manufacture tools, indexable inserts and rotationally-symmetrical tools in PCD PCBN and other hard metal. Year 2018, UNITED GRINDING offers it's EWAG PROFILE LINE, The machine integrates both EWAG ProGrindg and WALTER HELITRONIC TOOL STUDIO into it’s FANUC control unit to further expand the range of applications and improve insert geometries.

Customer Case-Vitrified Diamond Periphery Grinding Wheel for PCD Inserts on Ewamatic Linear

| Item | Details |

| Wheel Type | Vitrified Diamond Peripheral Grinding Wheel |

| Application | Peripheral Grinding PCD Inserts |

| Grinding Machine | Ewamatic Line |

| Wheel Sizes | 11A2-Φ200-W10-X10-H40 |

| Grit Sizes | D16 C125 |

| Workpiece Materail | Polycrystalline Diamond Inserts |

| Wheel Speed | 12m/s-30m/s |

| Grinding Pressure | Feed-on pressure at130-140Nm |

| Coolant Type | Oil |

| Ablation Rate | 0.07mm per plate |

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088