Grinding

Home / Grinding / PCD Grinding Machine > M50 Manual PCD Tool Grinder

M50 Manual Tool Grinder for grinding and regrinding pcd, cbn, ceramics, carbide and HSS tools

- Economical type PCD Grinder, Cost-effective

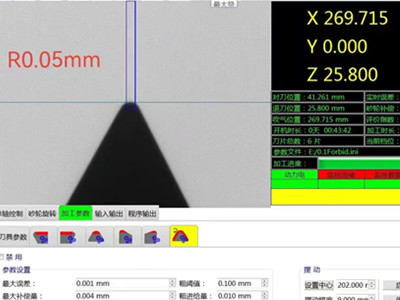

- Fast feeding and withdrawing, constant pressure grinding, on-line inspection

- Tip radius: R0.1 - R6 mm

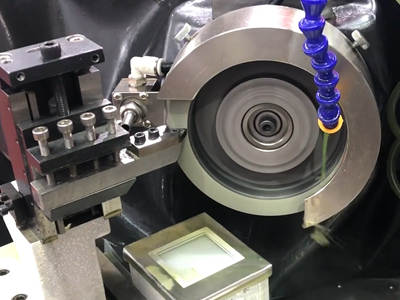

M50 tools grinding machine has characteristics of tight configuration , quick action and high sensitivity. The functions of the machine including fast feeding and withdrawing, constant pressure grinding, on-line inspection, wheel spindle oscillation controlling by servo motor, etc.

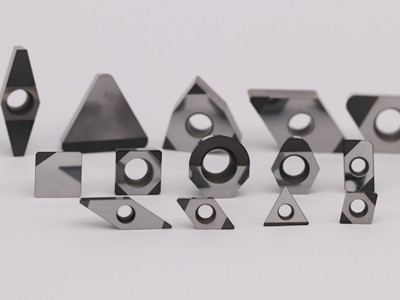

The M50 manual PCD machine is suitable for grinding or regrinding PCD, CBN, MCD, CVD tools, clip blade, non- standard turning tool, boring tool, ceramics, carbide and HSS tools, also can be used as tool grinding.

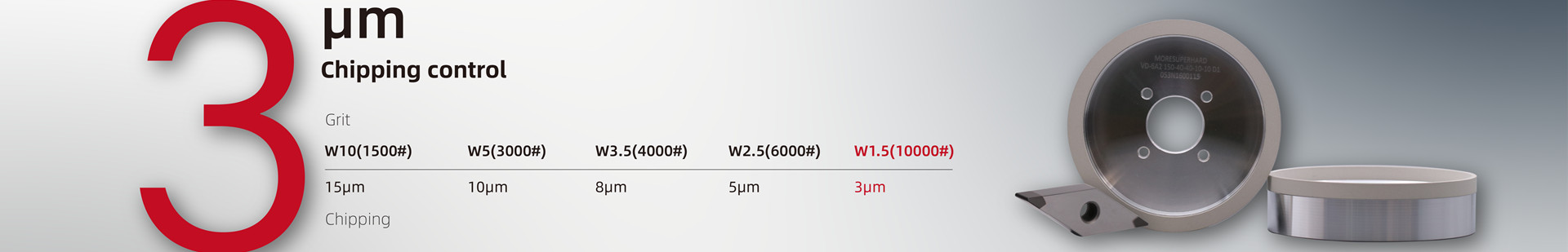

Technical Parameters - M50 Manual PCD Tool Grinder

|

Grinding spindle inclination: -5°- 25°

Tip radius: R0.1 - R5MM

Grinding spindle speed: 1000-4200 rpm

Spindle oscillation frequency: <= 40 strokes/min

Grinding spindle oscillation size: 0- 40mm

Grinding spindle motor power: 2.2kw

Vitrified diamond wheel size: 150x40x40

Total power: 3.5kw

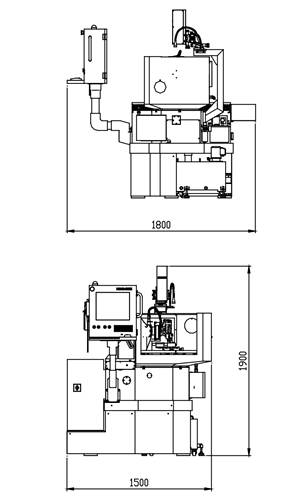

Dimension: 1500x1720x1850mm

Net weight: about 1200kg |

Object distance of lens: 300mm

Monitor size: 19”

Monitor resolution: 1600x900

Slider feeding size: 70mm

Worktable swiveling angle: 0-240°

Worktable travel: 60x60mm

Contact pressure: 0-400N

Optical scale resolution: 0.001mm

Encoder resolution: 0.036°

|

The Standard Configuration

- The main part of machine

- Power supply and control system

- Work station

- Imaging system

- Pneumatic unit

- Work light and backlight

- Coolant tank

- Grinding wheel dresser

- Adjustable quick mounting fixture

- Standard accessories

- Technical documentation

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

"Hyperion invests in a U.S. diamond and CBN manufacturing center, driving advancements in the superhard materials industry. Moresuperhard ’s PCD laser cutting machine delivers high-precision, heat-free, and efficient cutting solutions for PCD tool manufacturers, enhancing productivity and competitiveness."

PDC cutters are widely used for gas,oli drilling,coal minning etc.Grinding procession will directly influence the quality od PCD cutter.Moresuperhard provide diamond grinding wheel for grinding different parts of pdc cutter like surface grinding,external grinding wheel ,double-sided grinding disc and centerless grinding wheel.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088