.jpg)

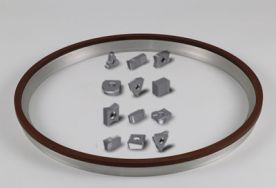

Peripheral grinding of indexable inserts (carbide, cermet insert)

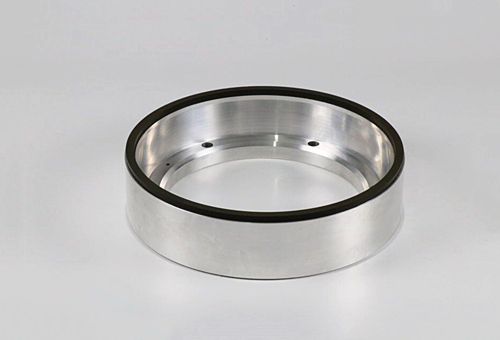

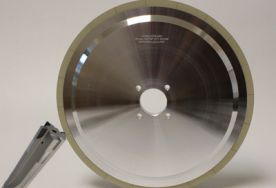

- Resin bond diamond peripheral wheel

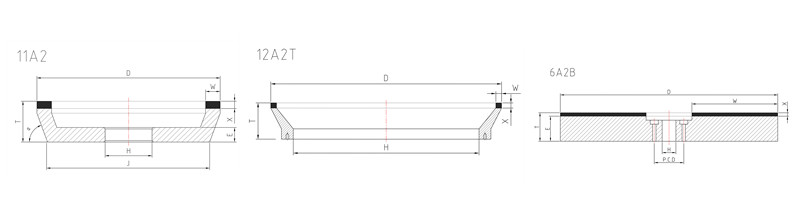

- Shape: 6A2T, 6A2H, 11A2, 11A2B, 2A2T, 11A2H, 12A2T, 15A2T

- Grinding Machines: Agathon, Ewag, HAAS, Waida, Wendt, Coborn, etc

What is indexable inserts?

Indexable insert is a cutting tool that is fixed in a tool holder and used for machining various materials, e.g. steel, wood, plastics, aluminum, etc. Indexable inserts can be used for all kinds of cutting applications – milling, turning, hole-making and threading. Majority of indexable inserts can be rotated to benefit from multiple (up to 8) cutting edges.

Indexable Inserts are made mainly by sintering metalic materials. Basic materials used for production of indexable inserts are tungsten carbides, cermets, technical ceramics and super-hard materials Polycrystalline Diamond (PCD) and Polycrystalline CBN (PCBN).

What grinding wheel is used for carbide and ceramic inserts

Resin diamond wheels are used for grinding carbide inserts and ceramic inserts.

- Optimised strength and increased brittleness

- Good stock removal rate and low cutting-edge chipping

- Suitable for tungsten carbide, cermet and ceramic materials

- Reduced grinding forces during machining

Specifications of peripheral grinding wheel for indexable inserts

|

Machining Material |

Bond type |

Shape |

Size |

Grinding machine |

||||

|

D |

W |

X |

T |

H |

||||

|

Tungsten carbide

ceramic inserts |

Resinous

Hybrid |

12A2T |

350 |

6 8 10 12 15 |

6 |

27 |

300 |

Agathon 350/400

Wendt |

|

400 |

6 8 10 12 15 |

6 |

28 |

340 |

||||

|

2A2M |

250 |

6 8 10 |

6 |

42 |

215 |

|||

|

CBN

PCD inserts |

Vitrified

Resin |

11A2B |

200 |

6 8 10 12

|

6 10 |

45 50

60 |

50

60 |

Waida Ewag

Coborn |

|

6A2B |

350 |

10 |

10 |

92 |

260 |

|||

|

Special size peripheral grinding wheels can be design, according to your requirement. |

||||||||

Dressing method for peripheral grinding wheel

A careful selection of an aluminum oxide and silicon carbide dressing tools are the perfect supplement to Moresuperhard grinding wheels that are optimized for the application. With the right bond and grain size, you can obtain the best possible sharpening and grinding results using our dressing wheels.

|

Dressing wheel |

Peripheral grinding wheel |

Application |

||||

|

Type |

Features |

Grit |

Bond of grinding wheel |

Grit |

Grinding method |

Material of inserts |

|

Ceramic aluminum oxide dressing wheel

|

Lower hardness, softer than silicon carbide grinding wheel. When dressing, it will not cause damage to diamond particles. It is the ideal choice for dressing peripheral grinding wheel.

|

120# |

Resin |

≥320# |

Peripheral grinding |

Cemented carbide, ceramic, cermet |

|

Metal |

>600# |

Peripheral grinding |

Cemented carbide,ceramic | |||

|

Ceramic |

>240# |

Peripheral grinding |

Cemented carbide,ceramic | |||

|

320# |

Resin |

<320# |

Peripheral grinding |

Cemented carbide, ceramic, cermet |

||

|

Metal |

≤600# |

Peripheral grinding |

Cemented carbide,ceramic |

|||

|

Ceramic |

≤240# |

Peripheral grinding |

PCBN,PCD |

|||

|

500# |

Ceramic |

≤1500# |

Peripheral grinding |

PCBN,PCD |

||

|

Ceramic Sic dressing wheel

|

High hardness, Suitable for dressing the profile of grinding wheel

|

80# |

Resin |

>120# |

Top and back face |

Cemented carbide, ceramic, cermet |

|

Metal |

>150# |

Top and back face |

Cemented carbide, ceramic |

|||

|

200# |

Resin |

≥240# |

Peripheral grinding |

Cemented carbide, ceramic, cermet |

||

|

Metal |

≥320# |

Peripheral grinding |

Cemented carbide, ceramic |

|||

Suitable for perpheral grinding machine

AGATHON

400 Series: 400PENTA, 400COMBI, 400SEMI, 400PERI.

350 Series: 350T&B, 350COMBI

250 Series: AGATHON, PA250

Wendt

400 Series: WAC715, WAC735

350 Series: WAM336

WAIDA

AP460E

WENT, WBN, WAIDA, VIOTTO, AMT, PETER WOLTERS, EWAG, etc.

You are our number one priority. We have tools available to assist in your product inquiries and general questions.

Diamond heat spreaders offer ultra-high thermal conductivity up to 2000 W/m·K, excellent electrical insulation, and outstanding chemical stability. Widely used in AI data centers, 5G/6G base stations, high-performance computing, aerospace, and power semiconductor modules, diamond thermal substrates significantly reduce chip junction temperature and enhance long-term device reliability.

Discover the core advantages of EDM machining for PCD saw blades, including non-contact processing, high precision tooth profiling, complex geometry capability, and improved efficiency for high-end cutting applications.

Add: Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86 17700605088